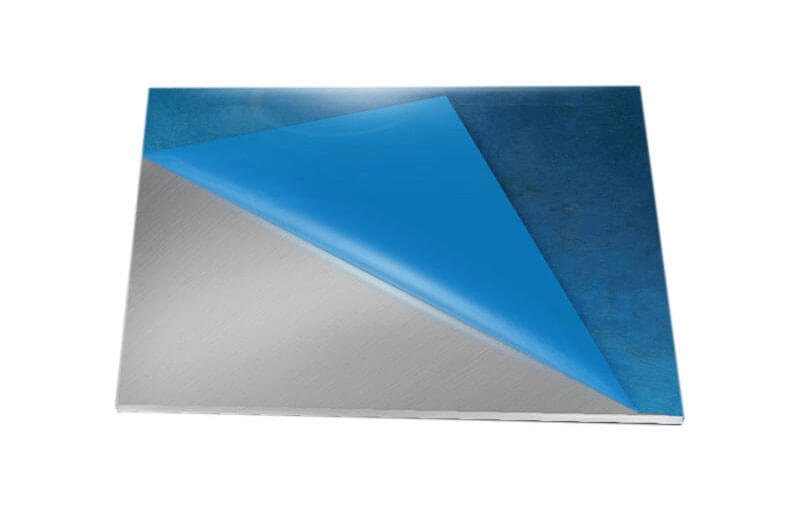

Aluminum alloy sheet

Product Introduction

Product Name | Aluminum Steel Sheet |

Grade | 1000Series 3000Series 5000Series 6000 Series 7000Series |

Tolerance | ±1% |

Application | Building decoration; Automobile manufacturing |

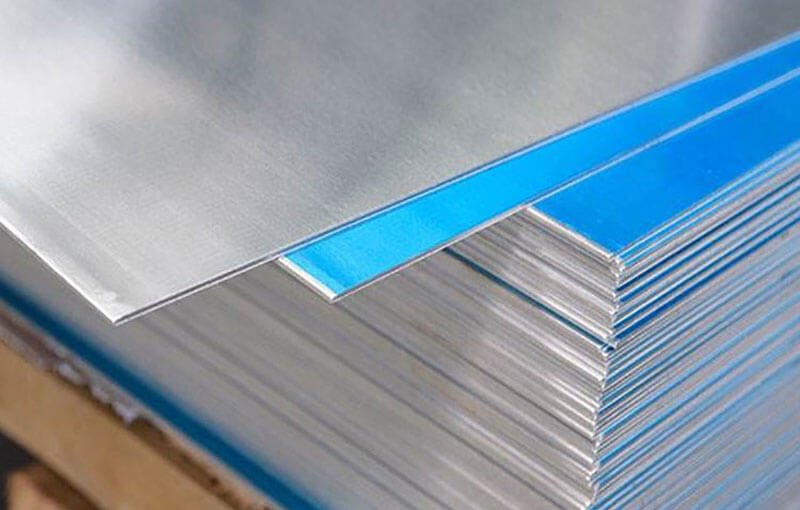

Width | 900mm-1500mm |

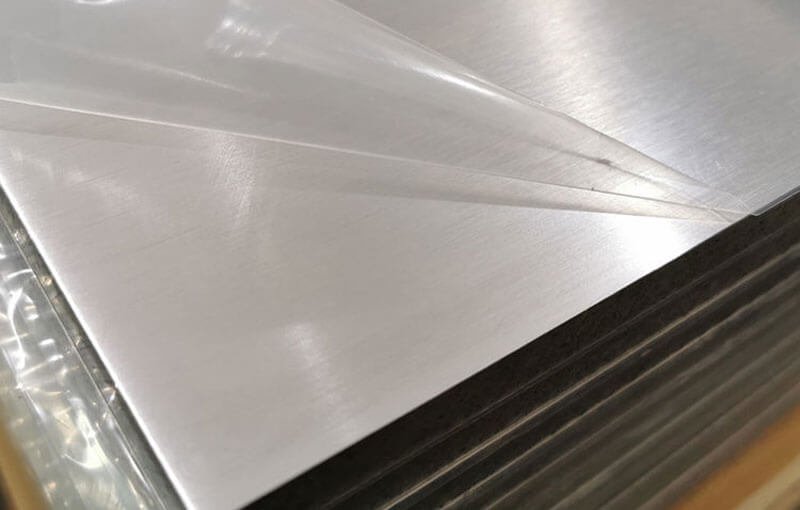

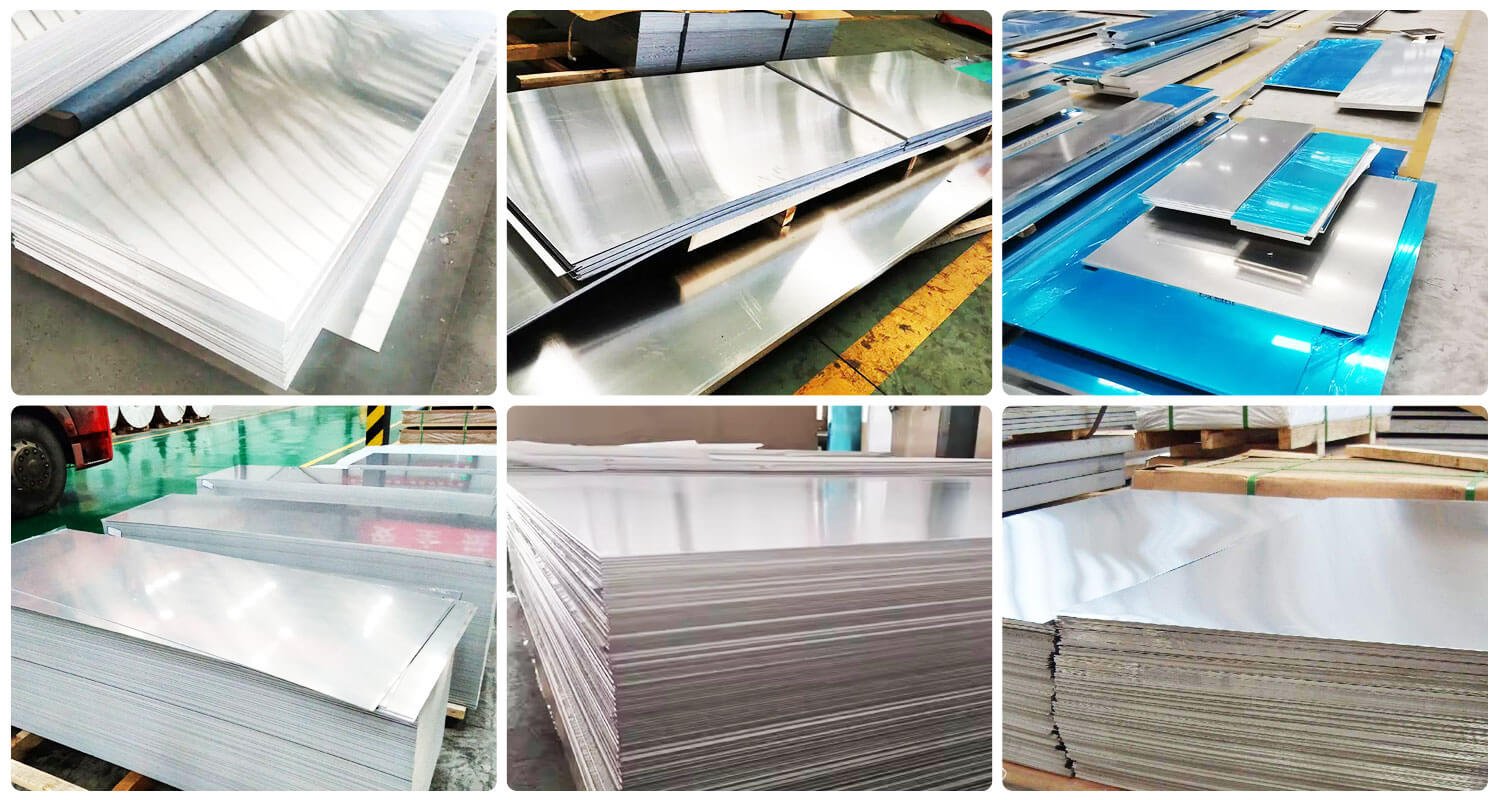

Surface Treatment | Coated |

Alloy Or Not | Is Alloy |

Brand Name | KAITAI |

Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

Color | Customized Color |

Payment Terms | 30%T/T Advance + 70% Balance |

Package | Standard Seaworthy Wooden Pallet Packing |

Sample | Provided |

Certification | ISO9001 CE |

Load Port | Tianjin Port |

Price term | FOB CIF CFR CNF DAP |

| Alloy Grade | Silicon (Si) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Chromium (Cr) | Zinc (Zn) | Titanium (Ti) | Other Single Elements | Total of Other Elements | Aluminum (Al) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1100 | ≤0.95 (Si + Fe) | – | 0.05 – 0.20 | – | – | – | – | 0.10 | 0.05 | 0.15 | ≥99.00 |

| 2011 | ≤0.40 | ≤0.7 | 5.0 – 6.0 | – | – | – | 0.30 | – | 0.05 | 0.15 | Remainder |

| 2024 | ≤0.50 | ≤0.50 | 3.8 – 4.9 | 0.30 – 0.9 | 1.2 – 1.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

| 3003 | ≤0.6 | ≤0.7 | 0.05 – 0.20 | 1.0 – 1.5 | – | – | 0.10 | – | 0.05 | 0.15 | Remainder |

| 5005 | ≤0.30 | ≤0.7 | ≤0.20 | ≤0.20 | 0.50 – 1.1 | 0.10 | 0.25 | – | 0.05 | 0.15 | Remainder |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2 – 2.8 | 0.15 – 0.35 | 0.10 | – | 0.05 | 0.15 | Remainder |

| 6061 | 0.40 – 0.8 | ≤0.7 | 0.15 – 0.40 | 0.15 | 0.8 – 1.2 | 0.04 – 0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

| 6063 | 0.20 – 0.6 | ≤0.35 | ≤0.10 | ≤0.10 | 0.45 – 0.9 | 0.10 | 0.10 | 0.10 | 0.05 | 0.15 | Remainder |

| 7010 | ≤0.12 | ≤0.15 | 1.5 – 2.0 | ≤0.10 | 2.1 – 2.6 | 0.05 | 5.7 – 6.7 | 0.06 | 0.05 | 0.10 | Remainder |

| 7050 | ≤0.12 | ≤0.15 | 2.0 – 2.6 | ≤0.10 | 1.9 – 2.6 | 0.04 | 5.7 – 6.7 | 0.06 | 0.05 | 0.15 | Remainder |

| 7075 | ≤0.40 | ≤0.50 | 1.2 – 2.0 | ≤0.30 | 2.1 – 2.9 | 0.18 – 0.28 | 5.1 – 6.1 | 0.20 | 0.05 | 0.15 | Remainder |

| Alloy Grade | Temper | Thickness (in) | Ultimate Tensile Strength (ksi) | Yield Strength (ksi) | Elongation % (in 2in or 4d) |

|---|---|---|---|---|---|

| 1100 | H14 | 0.009 – 0.012 | 16.0 – 21.0 | 14.0 | 1 |

| 1100 | H14 | 0.013 – 0.019 | 16.0 – 21.0 | 14.0 | 2 |

| 1100 | H14 | 0.020 – 0.031 | 16.0 – 21.0 | 14.0 | 3 |

| 1100 | H14 | 0.032 – 0.050 | 16.0 – 21.0 | 14.0 | 4 |

| 1100 | H14 | 0.051 – 0.113 | 16.0 – 21.0 | 14.0 | 5 |

| 1100 | H14 | 0.114 – 0.499 | 16.0 – 21.0 | 14.0 | 6 |

| 1100 | H14 | 0.500 – 1.00 | 16.0 – 21.0 | 14.0 | 10 |

| 3003 | H14 | 0.009 – 0.012 | 20.0 – 26.0 | 17.0 | 1 |

| 3003 | H14 | 0.013 – 0.019 | 20.0 – 26.0 | 17.0 | 2 |

| 3003 | H14 | 0.020 – 0.031 | 20.0 – 26.0 | 17.0 | 3 |

| 3003 | H14 | 0.032 – 0.050 | 20.0 – 26.0 | 17.0 | 4 |

| 3003 | H14 | 0.051 – 0.113 | 20.0 – 26.0 | 17.0 | 5 |

| 3105 | H14 | 0.013 – 0.019 | 22.0 – 29.0 | 18.0 | 1 |

| 3105 | H14 | 0.020 – 0.031 | 22.0 – 29.0 | 18.0 | 1 |

| 5052 | H32 | 0.017 – 0.019 | 31.0 – 38.0 | 23.0 | 4 |

| 5052 | H32 | 0.020 – 0.050 | 31.0 – 38.0 | 23.0 | 5 |

| 5052 | H34 | 0.009 – 0.019 | 34.0 – 41.0 | 26.0 | 3 |

| 5052 | H34 | 0.020 – 0.050 | 34.0 – 41.0 | 26.0 | 4 |

| 5083 | H116 | 0.063 – 0.499 | 44.0 | 31.0 | 10 |

| 5086 | H32 | 0.020 – 0.050 | 40.0 – 47.0 | 28.0 | 6 |

| 5086 | H116 | 0.063 – 0.249 | 40.0 | 28.0 | 8 |

| 5454 | O | 0.020 – 0.031 | 31.0 – 41.0 | 12.0 | 12 |

| 5454 | H32 | 0.020 – 0.050 | 36.0 – 44.0 | 26.0 | 5 |

| 6061 | T6 | 0.006 – 0.007 | 42.0 | 35.0 | 4 |

| 6061 | T6 | 0.008 – 0.009 | 42.0 | 35.0 | 6 |

| 6061 | T6 | 0.010 – 0.020 | 42.0 | 35.0 | 8 |

| 6061 | T651 | 0.250 – 0.499 | 42.0 | 35.0 | 10 |

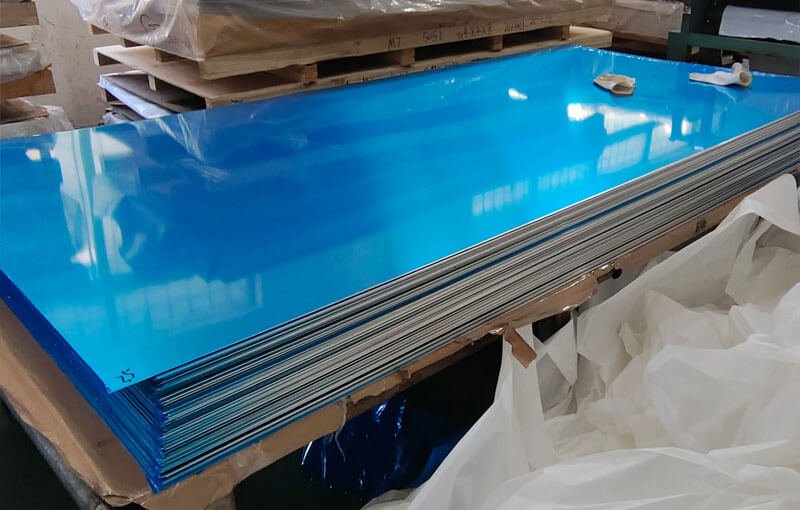

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.