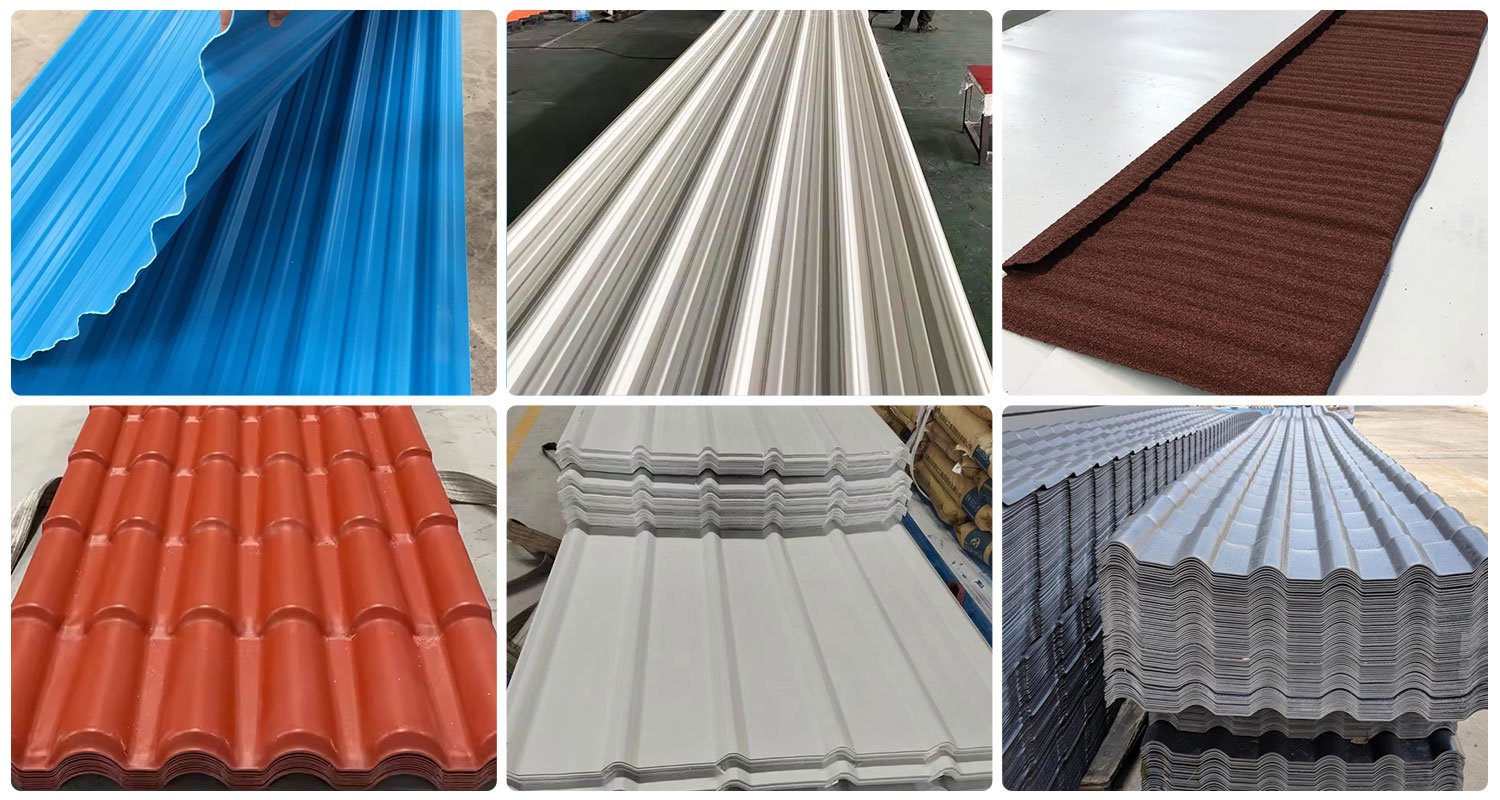

Roofing sheets

Product Introduction

| Category | Parameter | Galvanized Steel (e.g., TDC51D+Z) | Al-Zn Coated Steel (Galvalume) | Polycarbonate (PC) | Fiberglass (FRP) | Asphalt |

|---|---|---|---|---|---|---|

| Base Material & Coating | Base Material | Low-carbon steel (Q235 equivalent) | Low-carbon steel | Polycarbonate resin | Fiberglass + resin | Asphalt + fiber mat |

| Coating Type/Thickness | Zinc coating; 30–275 g/m² (total both sides) | Al-Zn alloy (55% Al, 43.5% Zn, 1.5% Si); 120–200 g/m² | UV-protective coating; 2–5 μm | Anti-UV gel coat; 0.2–0.5 mm | None | |

| Mechanical Performance | Yield Strength (MPa) | 270–500 | 280–550 | — (flexural) | — (flexural) | — |

| Tensile Strength (MPa) | 370–600 | 380–650 | 60–80 (tensile) | 80–120 (tensile) | — | |

| Elongation at Break (%) | ≥20 | ≥18 | 100–150 | 2–5 | — | |

| Impact Resistance | ≥27 J (Charpy, -40°C) | ≥27 J (Charpy, -40°C) | ≥10 kJ/m² (Izod) | ≥5 kJ/m² (Izod) | Low | |

| Load-Bearing Capacity (kN/m²) | 1.5–3.0 (depends on thickness/profile) | 1.8–3.5 (depends on thickness/profile) | 0.3–0.8 (needs supports) | 0.5–1.0 | 0.8–1.2 | |

| Dimensional Specifications | Thickness Range (mm) | 0.13–1.2 | 0.15–1.2 | 0.8–10 | 1.5–5 | 3–5 |

| Width Range (mm) | 600–1500 (effective width) | 600–1500 (effective width) | 600–2100 | 800–1500 | 900–1000 | |

| Length Range (m) | 1–12 (customizable) | 1–12 (customizable) | 2–6 | 2–10 | 1.8–2.4 | |

| Profile Type | Corrugated, Trapezoidal, Standing Seam | Corrugated, Trapezoidal, Standing Seam | Corrugated, Flat, Multi-wall | Corrugated, Flat | Corrugated | |

| Durability & Weather Resistance | Service Life (Years) | 15–30 (indoor: 30+, coastal: 10–15) | 20–40 (indoor: 40+, coastal: 15–25) | 10–20 (UV-stabilized) | 8–15 (anti-UV) | 8–12 |

| Corrosion Resistance | Good (zinc barrier); avoid heavy salt/acid | Excellent (Al oxide layer); better than galvanized | Excellent (no rust) | Excellent (chemical resistance) | Poor (moisture damage) | |

| UV Resistance | Good (with PVDF/SMP coating) | Excellent (with PVDF coating) | Good (UV-stabilized) | Fair (prone to yellowing) | Poor | |

| Thermal & Physical Properties | Thermal Conductivity (W/m·K) | 45–50 (steel core) | 45–50 (steel core) | 0.19–0.22 | 0.20–0.25 | 0.15–0.20 |

| Fire Rating | Class A (non-combustible) | Class A (non-combustible) | Class B1 (flame-retardant) | Class B2 (limited flame-retardant) | Class C | |

| Light Transmittance (%) | 0 (opaque) | 0 (opaque) | 50–90 (clear/translucent) | 40–80 (translucent) | 0 (opaque) | |

| Installation & Weight | Weight (kg/m²) | 5–12 (depends on thickness) | 5–13 (depends on thickness) | 1.2–3.0 | 1.5–4.0 | 8–12 |

| Installation Method | Screw fastening, seam locking | Screw fastening, seam locking | Screw/clip fastening | Screw fastening | Adhesive + fastening |

| Roofing Sheet Type | Component/Material | Chemical Composition (Mass %) | Remarks |

|---|---|---|---|

| Galvanized Steel Roofing Sheet (e.g., TDC51D+Z) | Base Metal | Low-carbon steel (mainly composed of Fe, with C content around 0.12%-0.20%, and small amounts of Mn, Si, S, P, etc.) | – |

| Zinc Coating | Zn: 99%+ | The coating amount is usually 30-275 g/m² (total on both sides) | |

| Al-Zn Coated Steel Roofing Sheet (Galvalume) | Base Metal | Low-carbon steel (similar to galvanized steel) | – |

| Al-Zn Alloy Coating | Al: 55%, Zn: 43.4%, Si: 1.6% | The coating amount is generally 120-200 g/m² | |

| Polycarbonate (PC) Roofing Sheet | Polycarbonate Resin | C, H, O | The main chain is composed of carbonate groups, with the chemical formula (C₁₆H₁₀O₃)ₙ |

| UV-protective Coating | Organic compounds containing UV-absorbing groups | The thickness is 2-5 μm | |

| Fiberglass (FRP) Roofing Sheet | Fiberglass | SiO₂, Al₂O₃, CaO, MgO, etc. | The content and proportion of each component vary depending on the type of glass fiber |

| Resin | Unsaturated polyester resin, vinyl ester resin, etc. | Mainly composed of C, H, O, and may contain N and other elements | |

| Asphalt Roofing Sheet | Asphalt | Hydrocarbons | Composed of various complex hydrocarbons |

| Fiber Mat | Glass fiber mat, organic fiber mat, etc. | – | |

| Additives | Fillers (such as calcium carbonate), stabilizers, plasticizers, etc. | – |

| Roofing Sheet Type | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (in 50mm, %) | Hardness (HV/HRB) | Bending Performance | Key Standards Reference |

|---|---|---|---|---|---|---|

| Galvanized Steel (e.g., TDC51D+Z) | 300 – 420 | ≥ 280 (for DX51D grade) | 18 – 25 | 80 – 120 HV / 60 – 80 HRB | 180° cold bend (no cracks); inner radius ≤ 1× sheet thickness | EN 10346, ASTM A653 |

| Al-Zn Coated Steel (Galvalume) | 310 – 430 | ≥ 280 (for AZ150 grade) | 17 – 24 | 85 – 125 HV / 62 – 82 HRB | 180° cold bend (no coating peeling); inner radius ≤ 1.5× sheet thickness | EN 10346, ASTM A792 |

| Color-Coated Steel (on Zn/Al-Zn base) | 300 – 450 | ≥ 280 (base metal-dependent) | 16 – 23 | 80 – 130 HV / 60 – 83 HRB | 180° cold bend (no paint cracking); inner radius ≤ 2× sheet thickness (paint-side out) | EN 10169, ASTM A755 |

| Polycarbonate (PC) Sheet | 55 – 75 | N/A (thermoplastic, no yield point) | 60 – 120 | 110 – 130 HV | Cold bend (no fracture); maximum bending radius ≥ 10× sheet thickness (depends on thickness) | ASTM D1003, EN 1288-3 |

| Fiberglass-Reinforced Plastic (FRP) | 80 – 200 (resin-dependent) | N/A | 2 – 8 (chopped strand mat) | 80 – 110 HV | Flexural strength: 120 – 250 MPa; no cracking under design load bending | ASTM D2571, EN 13706 |

| Aluminum Alloy Sheet (e.g., 3003-H14) | 110 – 145 | 95 – 130 | 10 – 18 | 35 – 45 HV / 60 – 70 HRB | 180° cold bend (no cracks); inner radius ≤ 0.5× sheet thickness | ASTM B209, EN 485-2 |

| Asphalt Roofing Sheet (organic felt) | 15 – 30 (tensile, lengthwise) | N/A | 3 – 8 (lengthwise) | N/A | Flexible at -20°C (no cracking); no delamination under repeated bending | ASTM D226, EN 13965 |

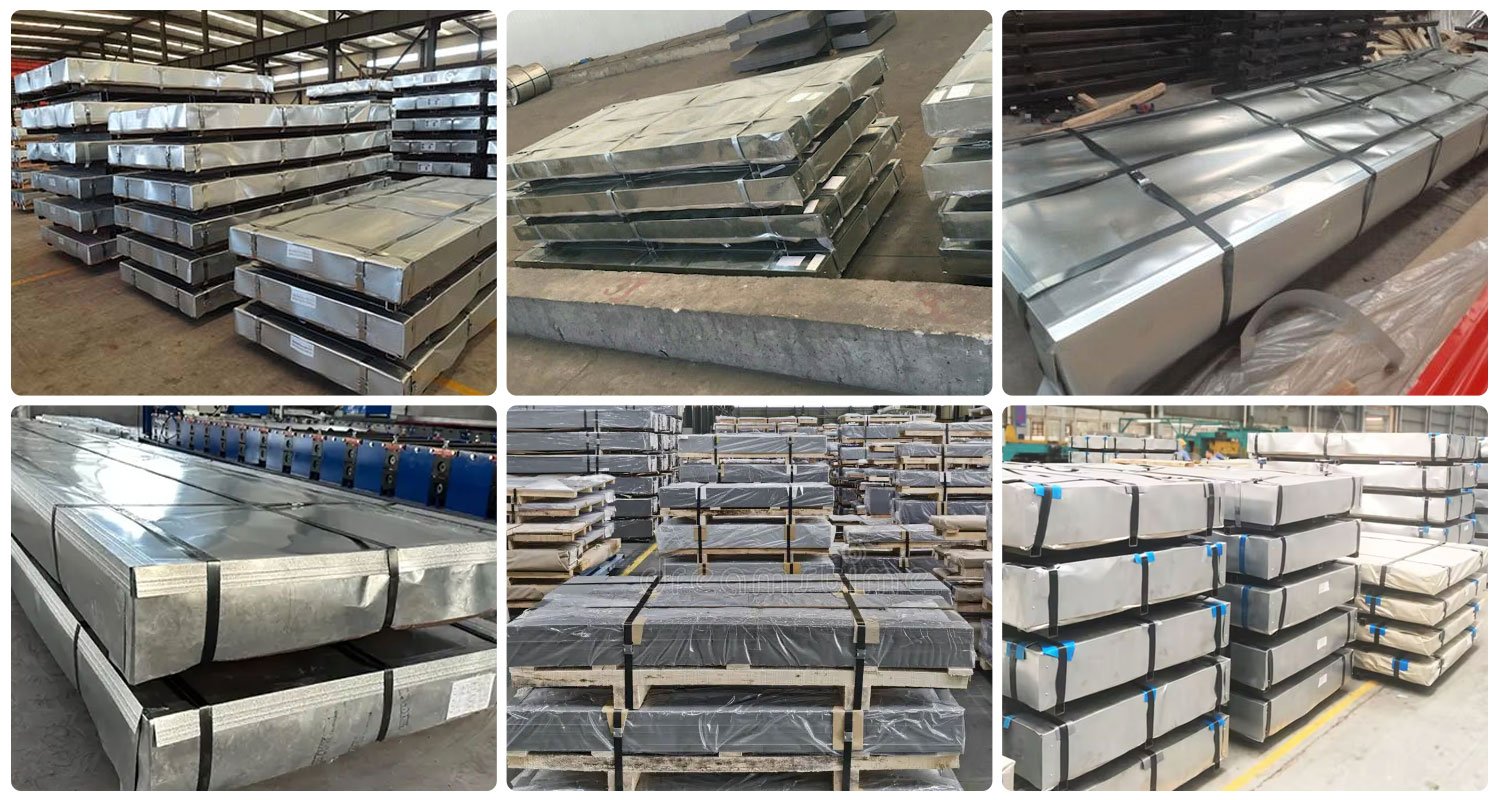

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.