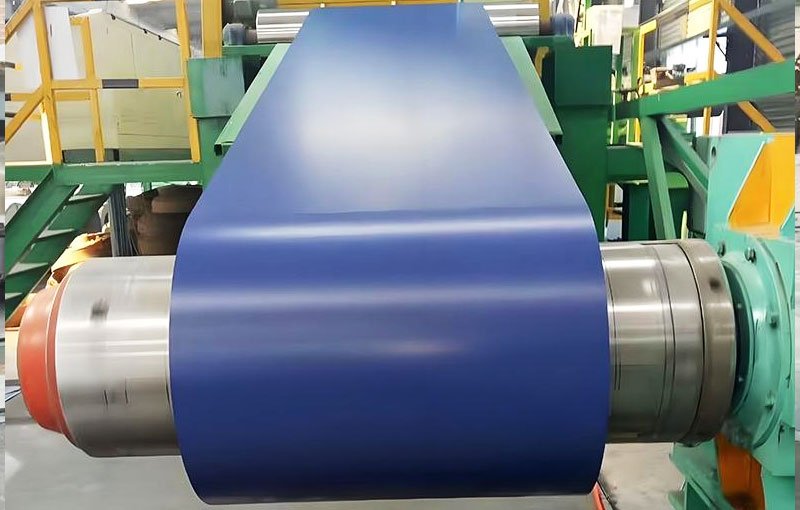

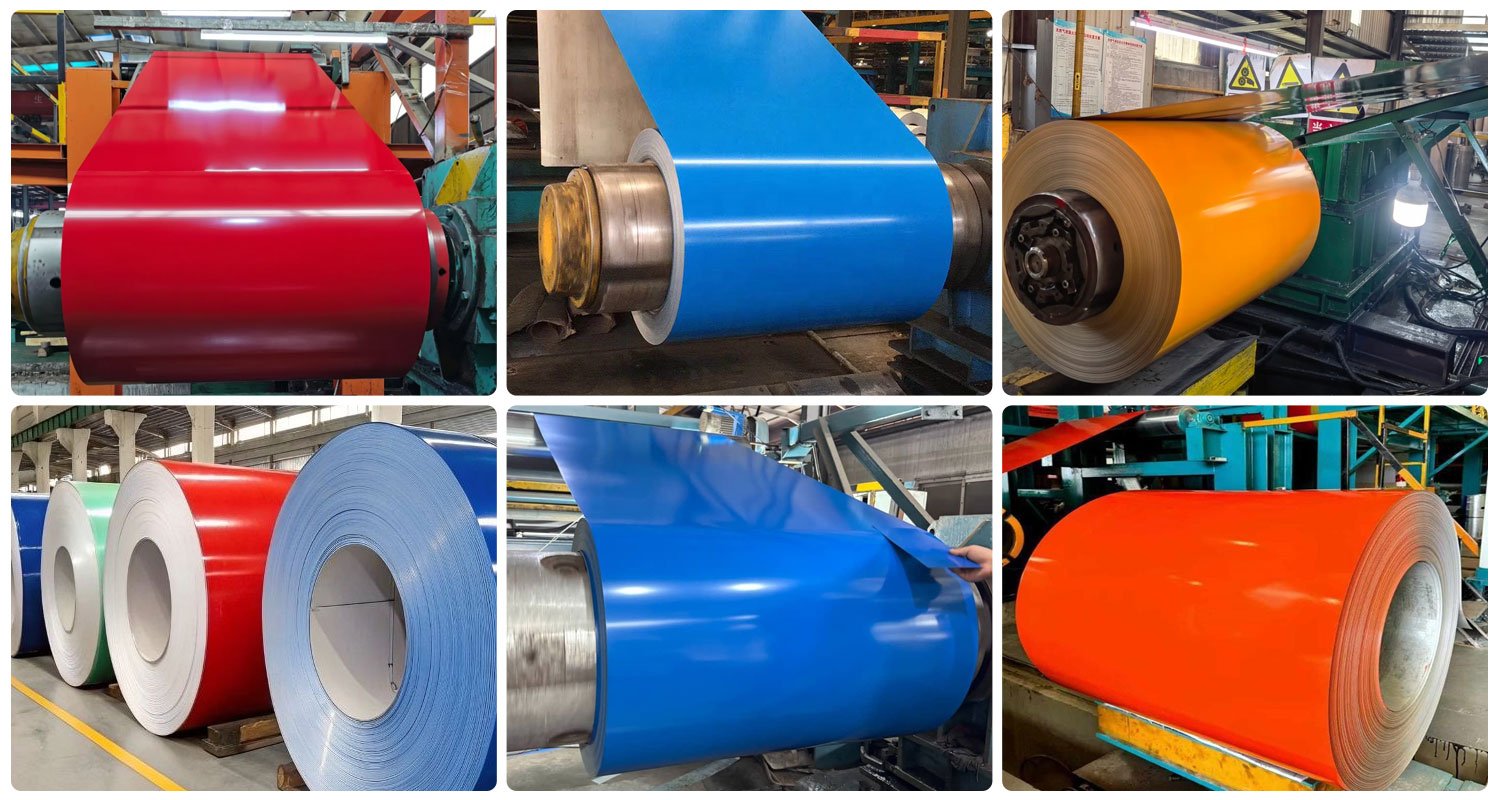

PPGL

Product Introduction

| Item | Specification |

|---|---|

| Product Name | Pre-painted Galvalume Steel (PPGL) |

| Base Metal | Low-carbon cold-rolled steel (Typical grade: DX51D, DX52D, or ASTM A1008) |

| Core Coating Type | 55% Al-Zn alloy coating (Galvalume, per EN 10346 / ASTM A792) |

| Standard Compliance | EN 10169 (Europe), ASTM A755 (North America), GB/T 12754 (China) |

| Typical Thickness Range | 0.25 mm – 1.2 mm (base metal + coatings) |

| Element | Symbol | Content (Maximum / Typical, wt%) | Remarks |

|---|---|---|---|

| Carbon | C | ≤ 0.12% | Reduces brittleness; ensures ductility |

| Manganese | Mn | ≤ 0.50% | Improves strength without excessive hardening |

| Silicon | Si | ≤ 0.05% | Minimizes surface defects in coating |

| Phosphorus | P | ≤ 0.025% | Controls corrosion sensitivity; avoids embrittlement |

| Sulfur | S | ≤ 0.025% | Reduces hot cracking risk during processing |

| Aluminum | Al | 0.02% – 0.06% | Deoxidizes molten steel; refines grain structure |

| Iron | Fe | Balance | Main matrix component of the base steel |

| Property | Test Standard | Unit | Typical Value (DX51D) | Typical Value (DX52D/ASTM A1008) |

|---|---|---|---|---|

| Yield Strength (YS) | ASTM E8 / EN ISO 6892 | MPa | 130 – 280 | 170 – 340 |

| Tensile Strength (TS) | ASTM E8 / EN ISO 6892 | MPa | 270 – 380 | 300 – 420 |

| Elongation (in 200mm gauge length) | ASTM E8 / EN ISO 6892 | % | ≥ 28 | ≥ 24 |

| Vickers Hardness (HV) | ASTM E92 / EN ISO 6507 | HV 0.5 | 60 – 90 | 70 – 100 |

| Bendability (180° bend test) | ASTM E290 / EN ISO 7438 | – | Pass (d = 0 × t¹) | Pass (d = 1 × t¹) |

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.