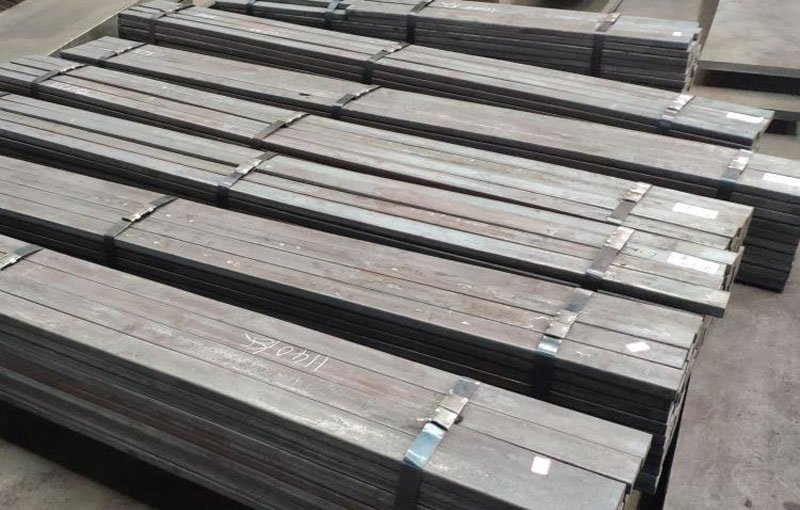

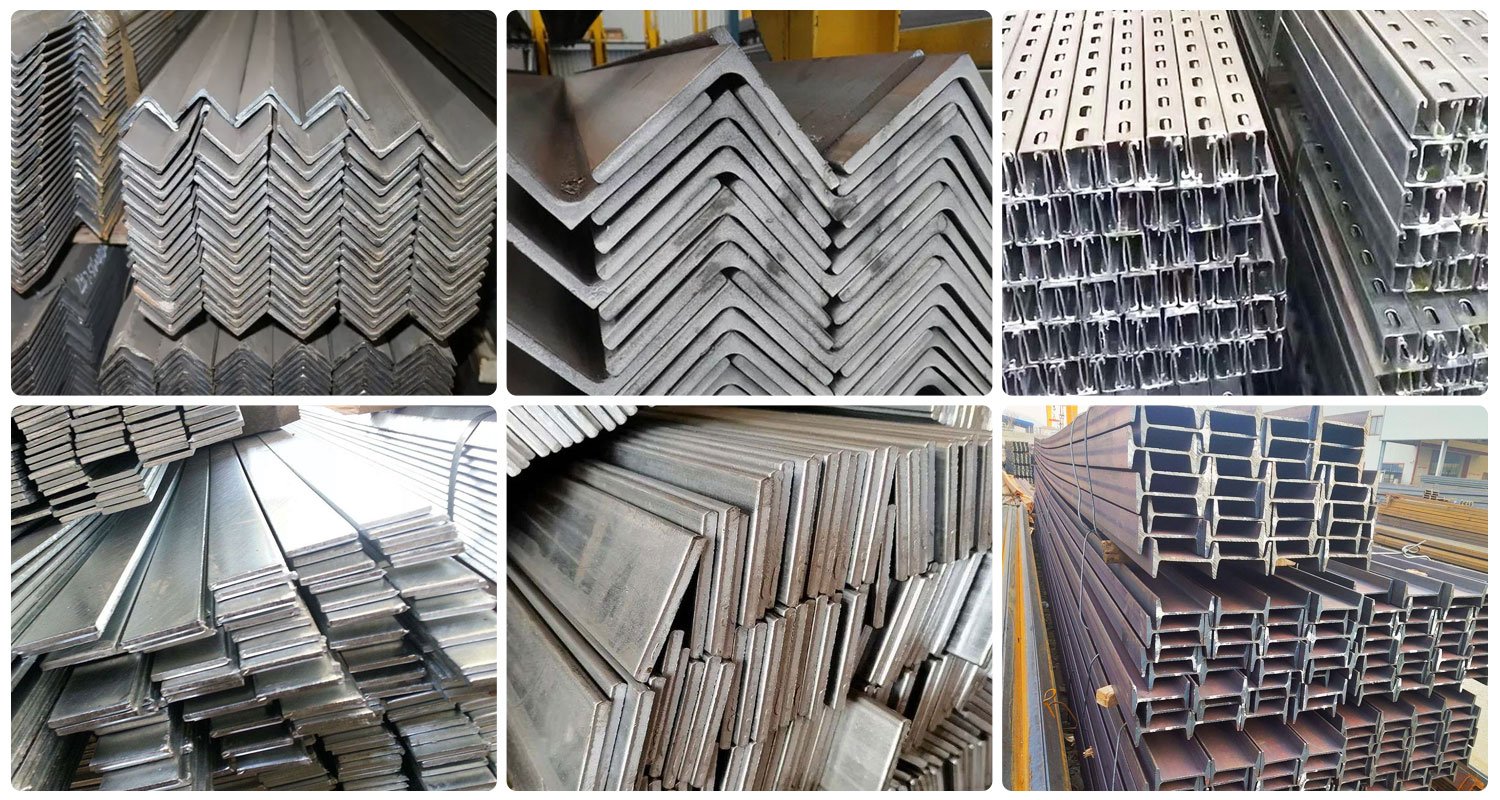

Carbon steel flat bars

Product Introduction

| Grade | Standard | C (Carbon) % | Mn (Manganese) % | P (Phosphorus) % (Max) | S (Sulfur) % (Max) | Si (Silicon) % | Other Elements |

|---|---|---|---|---|---|---|---|

| 1018 | ASTM A108 | 0.15–0.20 | 0.60–0.90 | 0.030 | 0.035 | 0.10–0.30 | — |

| 1044 | ASTM A108 | 0.40–0.48 | 0.70–1.00 | 0.030 | 0.035 | 0.10–0.30 | — |

| A36 | ASTM A36 | 0.25 (Max) | 0.85–1.20 | 0.040 | 0.050 | 0.40 (Max) | — |

| A572 Gr. 50 | ASTM A572 | 0.23 (Max) | 1.35 (Max) | 0.040 | 0.050 | 0.40 (Max) | V: 0.01–0.15 (Min) |

| 1020 | ASTM A108 | 0.18–0.23 | 0.30–0.60 | 0.030 | 0.035 | 0.10–0.30 | — |

| Material Grade | Applicable ASTM Standard | Carbon (C) % | Manganese (Mn) % | Phosphorus (P) % (Max) | Sulfur (S) % (Max) | Silicon (Si) % | Other Alloying Elements |

|---|---|---|---|---|---|---|---|

| 1018 | ASTM A108 (Cold-Finished) | 0.15 – 0.20 | 0.60 – 0.90 | 0.030 | 0.035 | 0.10 – 0.30 | None |

| 1018 | ASTM A36 (Hot-Rolled) | 0.18 – 0.25 | 0.80 – 1.10 | 0.040 | 0.050 | 0.15 – 0.40 | None |

| 1044 | ASTM A108 (Cold-Finished) | 0.40 – 0.48 | 0.70 – 1.00 | 0.030 | 0.035 | 0.10 – 0.30 | None |

| A36 | ASTM A36 (Hot-Rolled) | 0.25 (Max) | 0.85 – 1.20 | 0.040 | 0.050 | 0.40 (Max) | None |

| A572 Grade 50 | ASTM A572 | 0.23 (Max) | 1.35 (Max) | 0.040 | 0.050 | 0.40 (Max) | Vanadium (V): 0.01 – 0.15 |

| 1020 | ASTM A108 (Cold-Finished) | 0.18 – 0.23 | 0.30 – 0.60 | 0.030 | 0.035 | 0.10 – 0.30 | None |

| 1045 | ASTM A108 (Cold-Finished) | 0.43 – 0.50 | 0.60 – 0.90 | 0.030 | 0.035 | 0.10 – 0.30 | None |

| Material Grade | ASTM Standard | Ultimate Tensile Strength | Yield Tensile Strength | Elongation at Break | Shear Strength | Hardness | Density | Elastic Modulus | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|---|---|

| A36 | ASTM A36 | 58,000 psi (400 MPa) | 47,700 psi (315 MPa) | – | 43,500 psi (300 MPa) | Brinell 140 | 0.282 lb/in³ (7.8 g/cc) | – | – |

| 1018 (Cold Rolled) | ASTM A108 | 63,800 psi (440 MPa) | 53,700 psi (370 MPa) | – | 43,500 psi (300 MPa) | Brinell 126, Rockwell B71 | 0.284 lb/in³ (7.87 g/cc) | – | – |

| S235JR | EN 10058 | 360 – 510 N/mm² (MPa) | ≥235 N/mm² (MPa) (thickness < 16 mm) | ≥26% (thickness < 16 mm) | – | – | – | – | – |

| 1040 (equivalent to BS 970 080M40) | – | 660 MPa (95700 psi) (6 – 13 mm, hot rolled, cold drawn bright bar); 510 MPa (74000 psi) (diameter 150 – 250 mm, normalized bright bar) | 530 MPa (76900 psi) (6 – 13 mm, hot rolled, cold drawn bright bar); 245 MPa (35500 psi) (diameter 150 – 250 mm, normalized bright bar) | 7.0% (6 – 13 mm, hot rolled, cold drawn bright bar) | – | Brinell 146 – 197 (diameter 150 – 250 mm, normalized bright bar) | 7.85 g/cc (0.284 lb/in³) | – | – |

| AISI 1541H | – | 1158 MPa (oil quenched, fine grained, tempered at 425 °C) | 1034 MPa (oil quenched, fine grained, tempered at 425 °C) | 15% | – | Brinell 335 (oil quenched, fine grained, tempered at 425 °C) | 7.7 – 8.03×1000 kg/m³ | 190 – 210 GPa | 0.27 – 0.30 |

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.