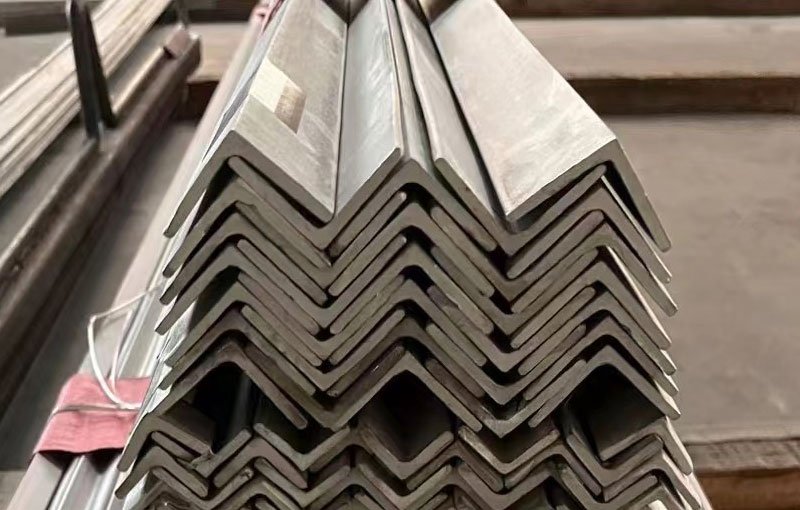

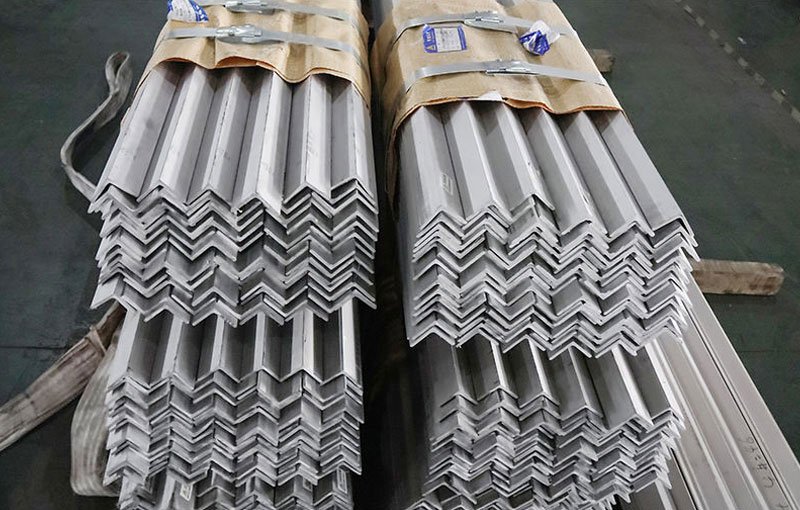

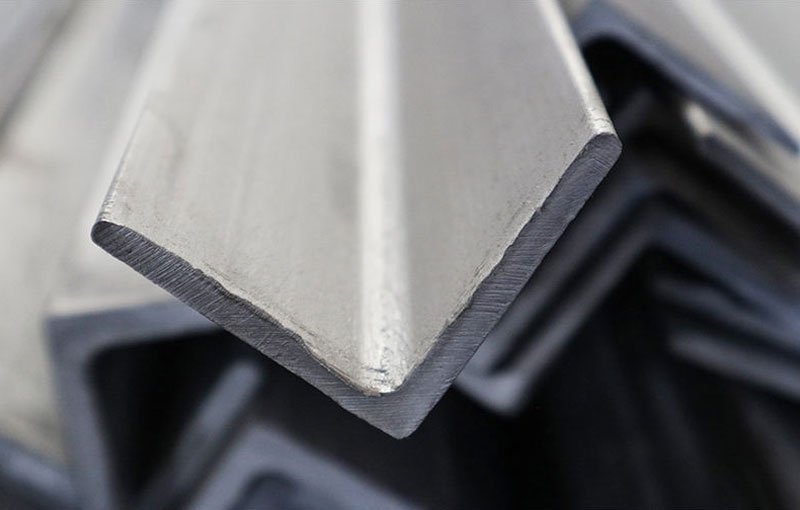

316 and 316L stainless steel angles belong to the same austenitic stainless steel family. They are “corrosion-resistant upgrades” based on 304/304L. Their core strength is the addition of molybdenum (Mo), which enhances their resistance to chloride ion corrosion. They are widely used in harsh environments such as those characterized by high salt concentrations, high humidity, and severe corrosion. Both have “L”-shaped cross-sections and highly similar performance, but differ in their carbon content, resulting in specific applications. As representatives of the “high-end corrosion-resistant” austenitic stainless steel, both inherit the fundamental advantages of austenitic steel while achieving breakthrough corrosion resistance thanks to the addition of molybdenum:

Excellent corrosion resistance (especially against chloride ion corrosion).

The core composition consists of 16%-18% chromium (Cr), 10%-14% nickel (Ni), and 2%-3% molybdenum (Mo). Chromium forms a passive film to protect against basic corrosion, while molybdenum further enhances the stability of the passive film, effectively inhibiting chloride ion (Cl⁻) damage to the film. As a result, its corrosion resistance to chloride-containing media such as seawater, salt water, chemical solutions (such as hydrochloric acid and sulfuric acid dilutions), and sweat is far superior to that of 304/304L (its chloride ion corrosion resistance is 2-3 times that of 304), earning it the nickname “marine-grade stainless steel.” Excellent high and low temperature performance

At low temperatures: It exhibits no brittle transition and can operate stably in the -196°C to 0°C range, making it suitable for low-temperature equipment supports (such as cold storage and liquid nitrogen tank perimeter structures).

At high temperatures: It can operate for short periods below 800°C, boasting superior oxidation resistance to 304, making it suitable for mildly high-temperature applications (such as oven supports and hot air blower housing supports).

Excellent machining and welding properties

Cold working: It can be formed through cold bending, achieving high cross-sectional dimensional accuracy. It supports cutting, drilling, and polishing (surface finishes include No. 1 industrial finish, No. 4 brushed finish, and mirror finish), making it suitable for complex installation requirements.

Welding: It can be welded using arc welding and argon arc welding (compatible with ER316L welding wire). The welded joint exhibits minimal strength loss, and due to its excellent corrosion resistance, the weld area is less susceptible to localized corrosion (but be aware of the risk of intergranular corrosion with 316; 316L does not). Balanced mechanical properties with non-magnetic properties at room temperature

At room temperature, it possesses a pure austenitic structure and is non-magnetic, making it suitable for applications requiring non-magnetic properties, such as electronic equipment and medical devices. Its mechanical properties are stable: a tensile strength of approximately 515 MPa, a yield strength of approximately 205 MPa, and an elongation of ≥40%. It offers sufficient strength to support structural loads (such as brackets and frames) while maintaining the toughness to avoid brittle fracture.