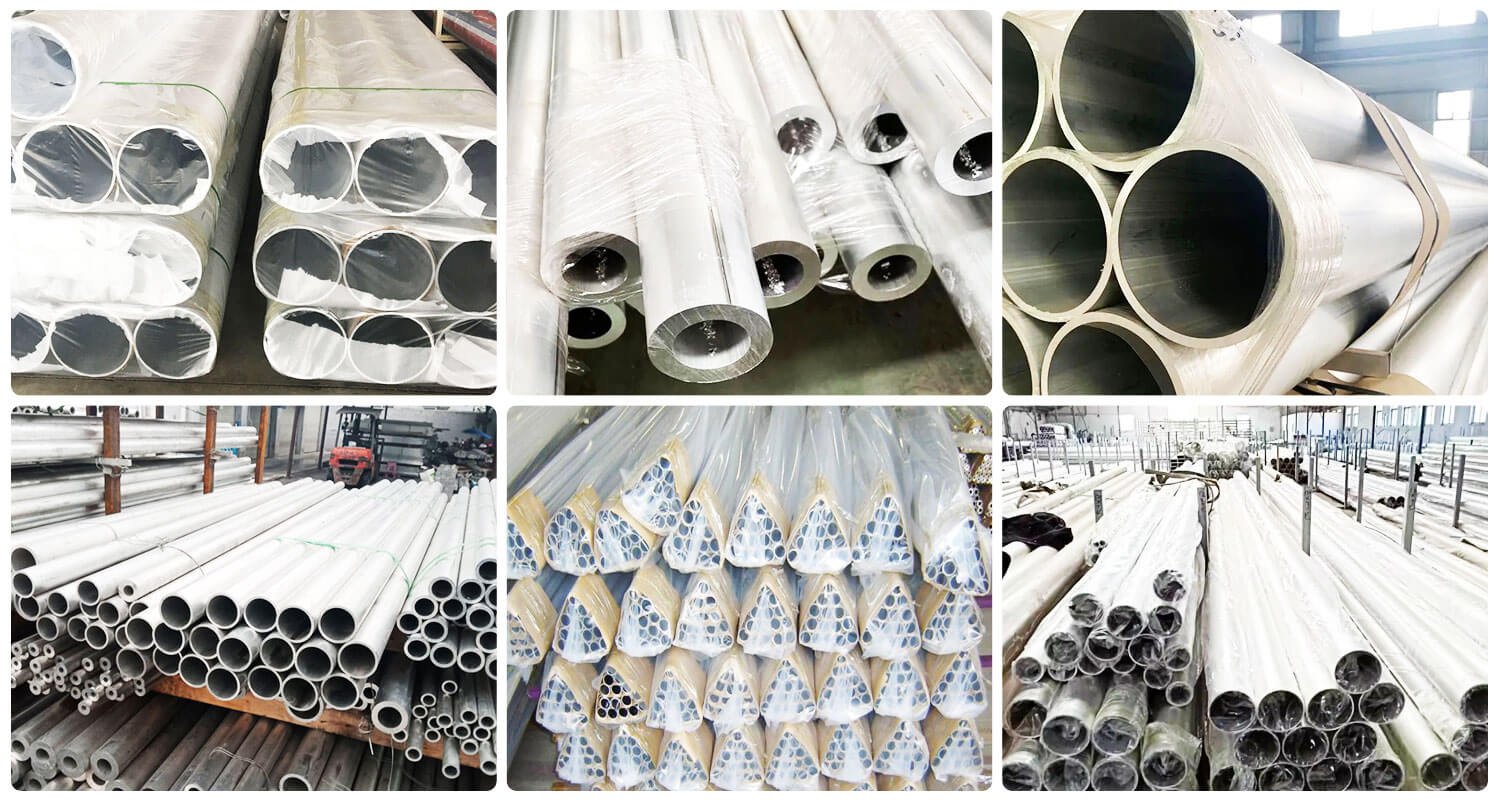

Aluminum alloy tube

Product Introduction

All specifications products can be customized according to customer requirements | |

Item | Aluminium pipe/tubes |

Grade | 1000 series: 1050,1060,1070,1080,1100,1435, etc |

2000 series: 2011,2014,2017,2024, etc | |

3000 series: 3002,3003,3104,3204,3030, etc | |

5000 series: 5005,5025,5040,5056,5083, etc | |

6000 series: 6101,6003,6061,6063,6020,6201,6262,6082, etc | |

7000 series: 7003,7005,7050,7075, etc | |

Standards | ASTM, ASME,EN, JIS, DIN,GB/T etc |

Size | Outer Diameter:3-250mm |

Wall Thickness: 0.3-50mm | |

Length: 10mm -6000mm | |

Surface treatment | Mill finish,Anodized,Electrophoresis,Powder coating,Wooden grain,Sand blast |

Surface colors | Nature, silver, bronze, champagne, black, gloden, etc As customized |

Temper | T3-T8/T351-T851/O-H112 |

Moulding/ Pattern | 1. Using our moulds, no fee |

2. Using customer drawing, opening mould, usually about 5 tons the moulding fee is free. | |

3. Can be diguessed. | |

Application | 1.Lighting,solar reflector plate. |

2.architectural appearance, interior decoration:ceiling,metope,furniture,cabinets and so on. | |

3.elevator,nameplate, bags. | |

4.automotive interior and exterior decoration. | |

5. Interior decoration: such as photo frame. | |

6.household appliances, refrigerator, microwave oven,audioequipment. | |

7. Aerospace aspects. | |

8, machinery parts processing, mold manufacturing . | |

9. chemical/insulation pipeline coating. | |

| Alloy Grade | Chemical Composition (mass fraction/%) |

|---|---|

| 1050 | Cu≤0.05, Si≤0.25, Fe≤0.40, Mn≤0.05, Mg≤0.05, Zn≤0.05, Al is the remainder |

| 5052 | Si≤0.25, Fe≤0.40, Cu≤0.10, Mn≤0.10, Mg = 2.2 – 2.8, Cr = 0.15 – 0.35, Zn≤0.10, Al is the remainder, each impurity≤0.05, total impurities≤0.15 |

| 5251 | Si = 0.40, Fe = 0.50, Cu = 0.15, Mn = 0.10 – 0.50, Mg = 1.7 – 2.4, Cr = 0.15, Zn = 0.15, Ti = 0.15, Al is the remainder |

| 6061 | Si = 0.4 – 0.8, Fe≤0.7, Cu = 0.15 – 0.4, Mn≤0.15, Mg = 0.8 – 1.2, Cr = 0.04 – 0.35, Zn≤0.25, Ti≤0.15, Al is the remainder |

| Alloy Grade | Temper | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation % (in specified gauge length) | Hardness (HBW) |

|---|---|---|---|---|---|

| 1100 | O | ≥90 | ≥35 | ≥30 | – |

| 3003 | O | ≥110 | ≥45 | ≥25 | – |

| 3003 | H12 | ≥130 | ≥120 | ≥8 | – |

| 3003 | H14 | ≥150 | ≥140 | ≥6 | – |

| 5052 | O | ≥170 | ≥70 | ≥20 | – |

| 5052 | H32 | ≥210 | ≥180 | ≥10 | – |

| 5083 | O | ≥270 | ≥115 | ≥12 | – |

| 6061 | O | ≥180 | ≥80 | ≥25 | – |

| 6061 | T4 | ≥205 | ≥110 | ≥14 (for thickness ≤12.5mm, gauge length A) or ≥12 (A50) | – |

| 6061 | T6 | ≥260 | ≥240 | ≥8 | – |

| 6063 | O | ≥130 | ≥70 | ≥25 | – |

| 6063 | T5 | ≥205 | ≥170 | ≥8 | – |

| 6063 | T6 | ≥230 | ≥205 | ≥8 | – |

| 6082 | O, H111 | ≤160 | ≤110 | ≥15 (A) or ≥13 (A50) | 35 |

| 6082 | T4 | ≥205 | ≥110 | ≥14 (A) or ≥12 (A50) | 70 |

| 6082 | T6 | ≥310 | ≥255 (for t≤5mm) or ≥240 (for 5mm<t≤20mm) | ≥8 (A) or ≥7 (A50) (for t≤5mm), ≥10 (A) or ≥9 (A50) (for 5mm<t≤20mm) | 95 |

| 7075 | O | ≥330 | ≥150 | ≥17 | – |

| 7075 | T6 | ≥505 | ≥435 | ≥11 | – |

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.