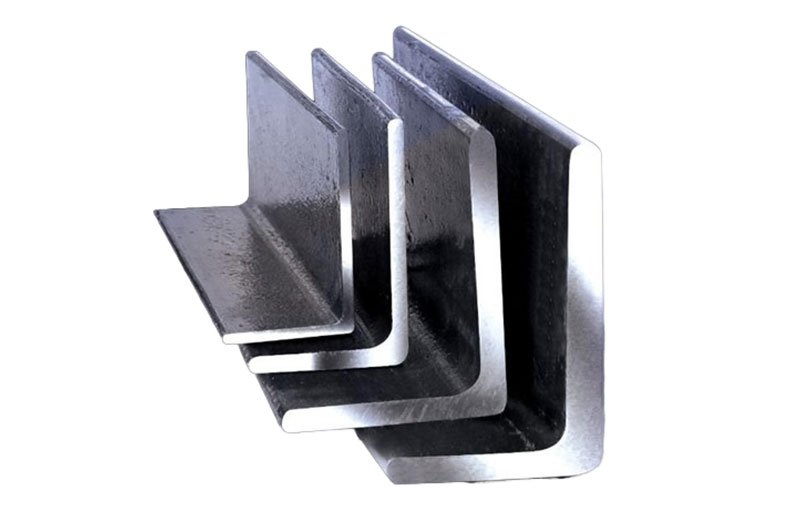

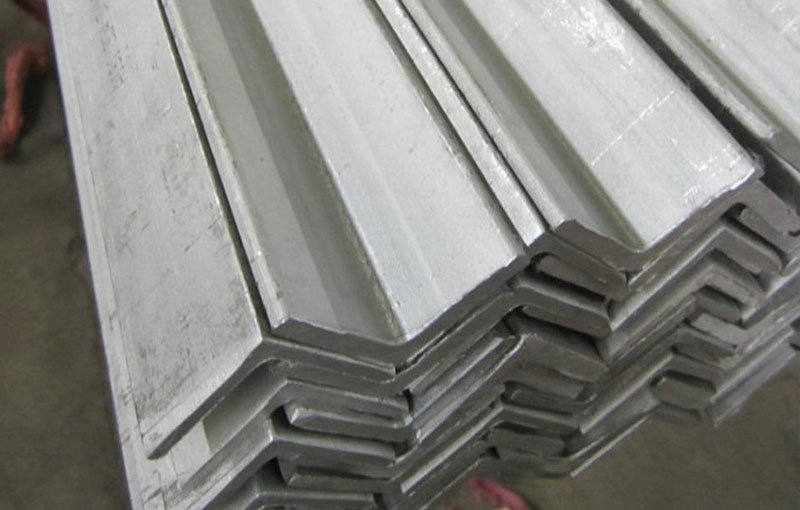

Angle steel stainless steel

Product Introduction

1. Geometric Dimensions and Tolerances

| Parameter | Symbol | Unit | Description |

|---|---|---|---|

| Leg Width | b | mm | The length of the two right – angled sides of the angle steel. For equal – leg angle steel, the two leg widths are equal; for unequal – leg angle steel, they are not equal. |

| Leg Thickness | t | mm | The thickness of the right – angled side. |

| Sectional Area | A | cm2 | The total area of the cross – section of the angle steel, which can be calculated according to the leg width and leg thickness. |

| Theoretical Weight | W | kg/m | Calculated according to the formula, it represents the weight per unit length of the angle steel. |

| Dimensional Tolerance of Leg Width | – | mm | For example, when the leg width is 20mm, the tolerance is ±1.0mm; when the leg width is 25 – 50mm, the tolerance is ±0.6mm. |

| Dimensional Tolerance of Leg Thickness | – | mm | Such as when the leg thickness is 3 – 6mm, the tolerance is ±0.4 – ±0.6mm. |

| Squareness | – | ° | It should be 90°±2°. |

| Warpage | – | mm/m | ≤3mm/m. |

2. Mechanical Properties

| Parameter | Symbol | Unit | Description |

|---|---|---|---|

| Tensile Strength | Rm | MPa | The maximum stress that the material can withstand during the tensile process. |

| Yield Strength | ReL or Rp0.2 | MPa | The stress at which the material begins to yield plastic deformation. |

| Elongation | A | % | The percentage of the increase in length after the material is broken during the tensile test compared to the original length. |

| Hardness | – | HB or HRB | Used to measure the hardness of the material, such as Brinell hardness (HB) or Rockwell hardness (HRB). |

3. Chemical Composition (Taking 304 Stainless – Steel Angle Steel as an Example)

| Element | Symbol | Content Range |

|---|---|---|

| Carbon | C | ≤0.08% |

| Chromium | Cr | 18.00 – 20.00% |

| Nickel | Ni | 8.00 – 10.50% |

| Manganese | Mn | ≤2.00% |

| Silicon | Si | ≤1.00% |

| Phosphorus | P | ≤0.045% |

| Sulfur | S | ≤0.030% |

| Grade | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) |

|---|---|---|---|---|---|---|---|---|

| 201 | ≤0.15% | ≤1.00% | 5.5 – 7.5% | ≤0.060% | ≤0.030% | 3.5 – 5.5% | 16.0 – 18.0% | – |

| 301 | ≤0.15% | ≤1.0% | ≤2.0% | ≤0.045% | ≤0.03% | 6.0 – 8.0% | 16.0 – 18.0% | – |

| 304 | ≤0.08% | ≤1.00% | ≤2.00% | ≤0.045% | ≤0.030% | 8.0 – 10.50% | 18.0 – 20.0% | – |

| 304L | ≤0.030% | ≤1.00% | ≤2.00% | ≤0.045% | ≤0.030% | 9.0 – 13.50% | 18.0 – 20.0% | – |

| 316 | ≤0.045% | ≤1.00% | ≤2.00% | ≤0.045% | ≤0.030% | 10.0 – 14.0% | 16.0 – 18.0% | 2.0 – 3.0% |

| 316L | ≤0.030% | ≤1.00% | ≤2.00% | ≤0.045% | ≤0.030% | 12.0 – 15.0% | 16.0 – 18.0% | 2.0 – 3.0% |

| 430 | ≤0.12% | ≤0.75% | ≤1.00% | ≤0.040% | ≤0.030% | ≤0.60% | 16.0 – 18.0% | – |

| 2507 | ≤0.03% | ≤0.8% | ≤1.2% | ≤0.035% | ≤0.02% | 6 – 8% | 24 – 26% | – |

| Grade | Tensile Strength | Yield Strength | Elongation | Hardness | Elastic Modulus | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| 201 | 685 – 696MPa (99400 – 101000Psi) | 292 – 301MPa (42400 – 43700Psi) | 56% – 62.5% | Rockwell B 85 | 197GPa (28573Ksi) | 0.27 – 0.30 |

| 304 | 500 – 700N/mm² (72520 – 101526Psi) | ≥175N/mm² (≥25381Psi) | – | ≤215HB | – | – |

| 304L | 620MPa (90000Psi) | 276MPa (40000Psi) | 50% | 70HRB | – | – |

| 316L | ≥515MPa (≥74708Psi) | ≥205MPa (≥29733Psi) | ≥40% | ≤201HBW; ≤92HRB; ≤210HV | 193KN/mm² | – |

| 310 | 515MPa (75000Psi) | 205MPa (30000Psi) | 40% | – | – | – |

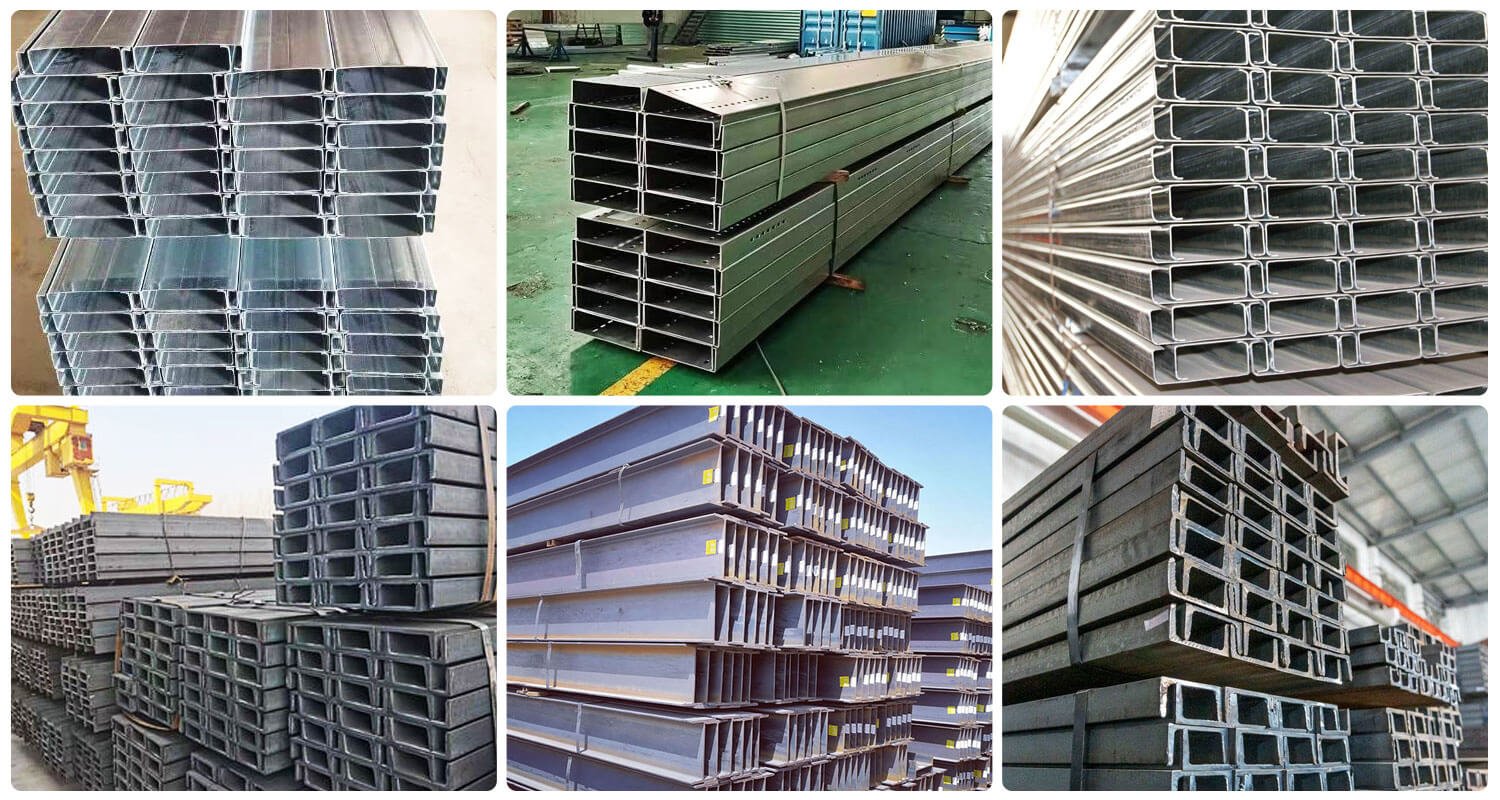

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.