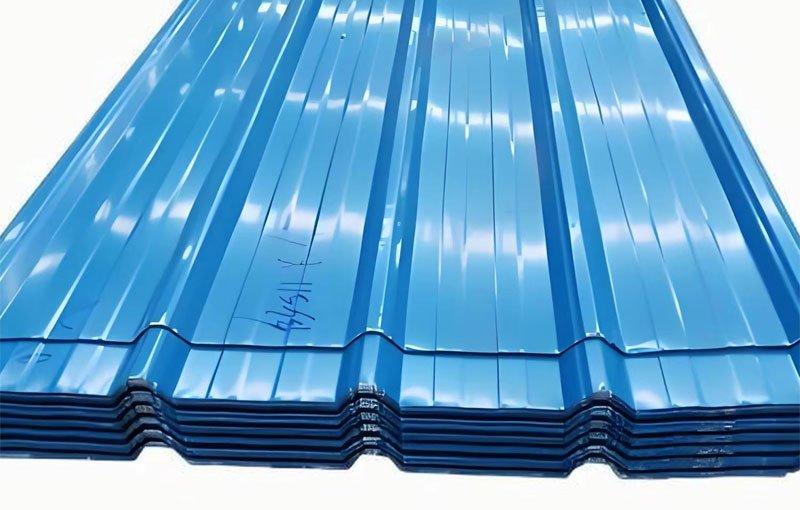

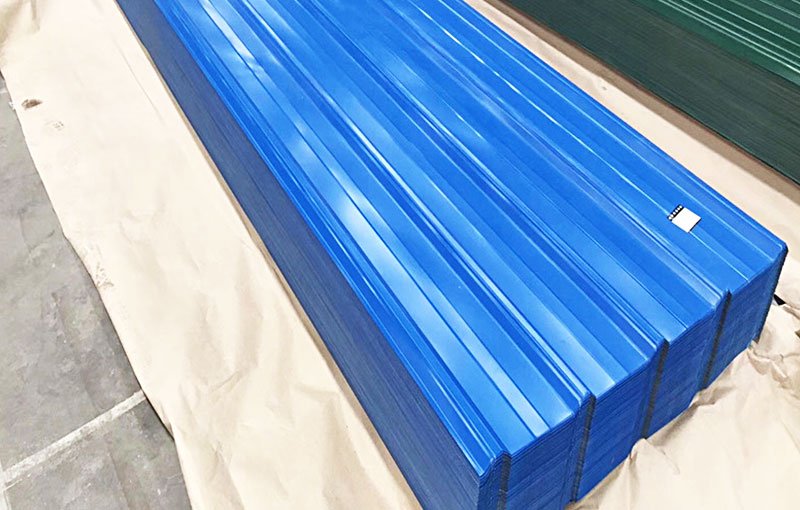

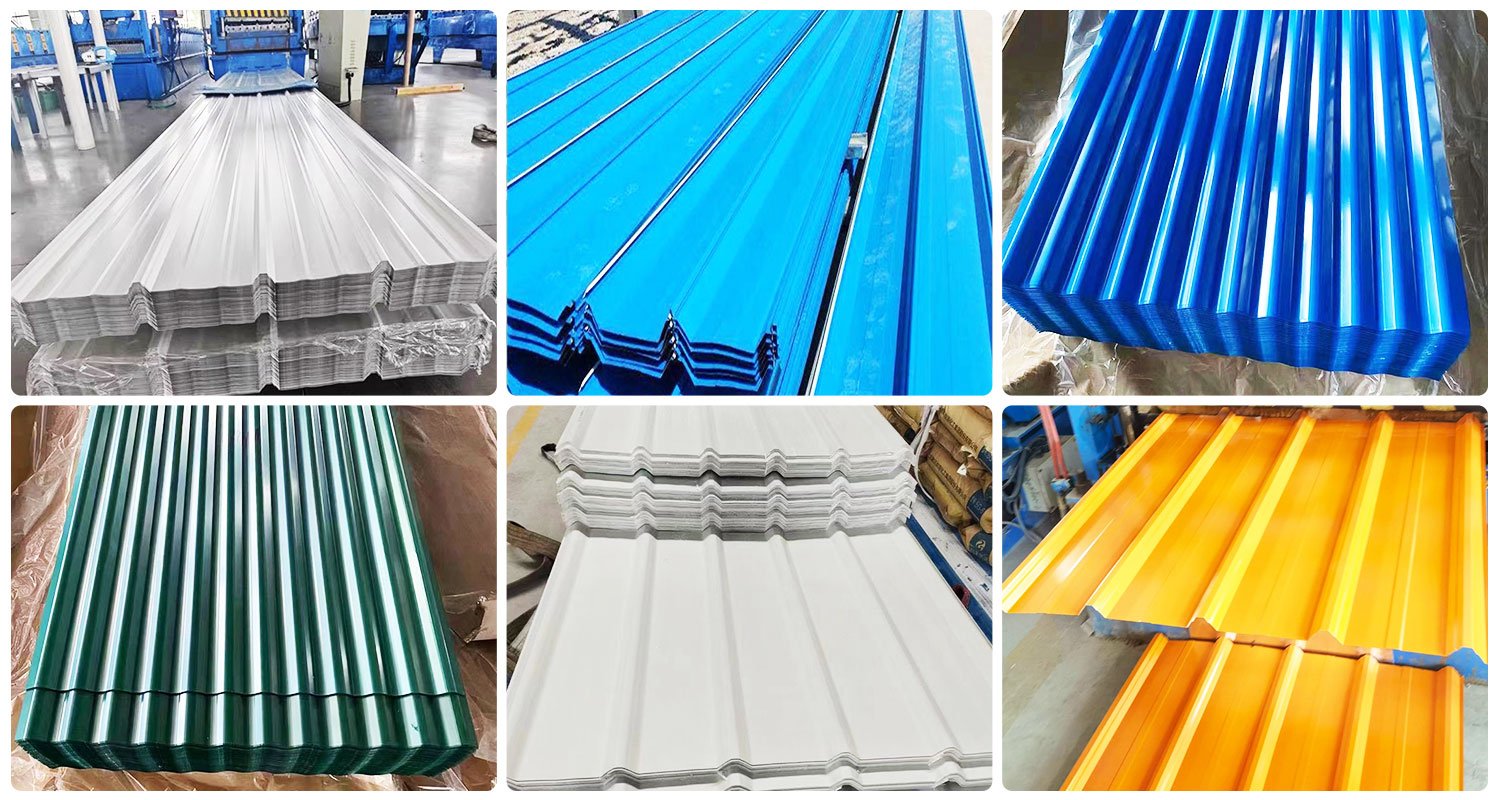

Color Steel Tile

Product Introduction

| Parameter | Description |

|---|---|

| Model | Such as Wanzhi – 14 – 63.5 – 850, Wanzhi – 25 – 210 – 840, etc. |

| Thickness | Usually ranges from 0.2mm to 1.5mm, with 0.4 – 0.6mm being the most common. For example, in the Wanzhi – 14 – 63.5 – 850 model, the thickness can be 0.5mm, 0.6mm or 0.8mm. |

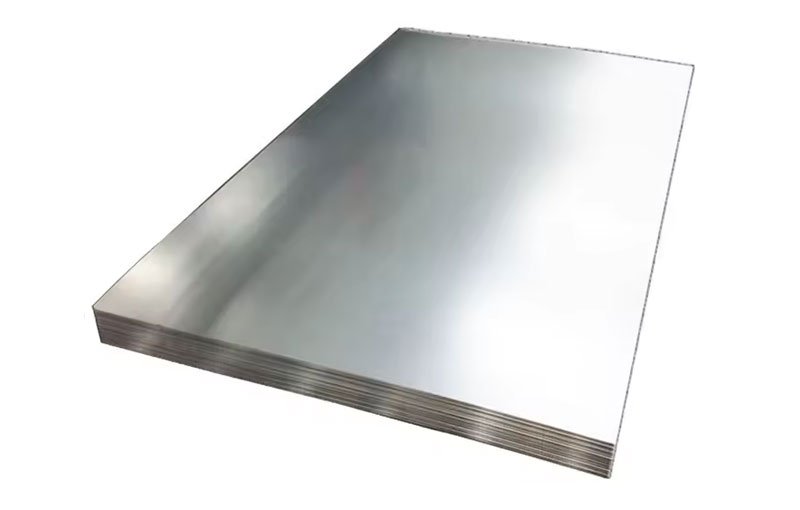

| Base Metal | Galvanized steel (e.g., TDC51D+Z), aluminum – zinc steel (e.g., AZ150), etc. |

| Zinc Coating Weight | For galvanized steel, it can be 50 – 275 g/m²; for aluminum – zinc steel, the coating weight is usually expressed as AZ150 (meaning 150 g/m² of the aluminum – zinc alloy coating). |

| Overall Width | The width of the steel tile before profiling. For example, for many models, the overall width is 1000mm. |

| Effective Width | The actual width covered after installation. For instance, the effective width of the Wanzhi – 14 – 63.5 – 850 model is 850mm. |

| Wave Height | Such as 14mm in the Wanzhi – 14 – 63.5 – 850 model, 25mm in the Wanzhi – 25 – 210 – 840 model. |

| Wave Pitch | Like 63.5mm in the Wanzhi – 14 – 63.5 – 850 model, 210mm in the Wanzhi – 25 – 210 – 840 model. |

| Tensile Strength | ≥280 MPa for TDC51D+Z; ≥350 MPa for high – strength grades. |

| Elongation | ≥20% for TDC51D+Z. |

| Coating Type | Polyester (PE), Silicon – Modified Polyester (SMP), Polyvinylidene Fluoride (PVDF), Polyurethane (PU), etc. |

| Coating Thickness | Varies according to different coating types and requirements. |

| Corrosion Resistance | ≥500h neutral salt spray test (no red rust for galvanized substrate). |

| Weather Resistance | ≤5% color fading (PVDF coating after 2000h UV test). |

| Sectional Moment of Inertia | Different for various models. For example, for the Wanzhi – 14 – 63.5 – 850 model with a thickness of 0.5mm, it is 1.84 cm⁴/m. |

| Section Resistance Moment | Also varies by model. For the Wanzhi – 14 – 63.5 – 850 model with a thickness of 0.5mm, it is 2.04 cm³/m. |

| Component | Content Range | Remarks |

|---|---|---|

| Iron (Fe) | ≥95% | The main component of the base steel, providing basic mechanical strength. |

| Carbon (C) | Usually less than 0.2% | Affects the strength and hardness of the steel. An increase in carbon content will increase the strength and hardness of the steel, but reduce its plasticity and toughness. |

| Silicon (Si) | Usually around 0.1%-0.5% | Improves the strength and hardness of the steel, and also has a certain effect on improving the corrosion resistance of the steel. |

| Manganese (Mn) | Usually around 0.3%-1.0% | Can improve the strength and toughness of the steel, and also has a certain deoxidation and desulfurization effect. |

| Phosphorus (P) | ≤0.045% | An impurity element that will increase the brittleness of the steel, especially at low temperatures, and is harmful to the performance of the steel. |

| Sulfur (S) | ≤0.035% | An impurity element that will form low-melting-point compounds with iron, reducing the hot workability and toughness of the steel. |

| Zinc (Zn) | For galvanized steel, the coating weight is 50-275g/m²; for aluminum-zinc steel, it is usually part of the aluminum-zinc alloy coating | Forms a protective film on the surface of the steel to prevent corrosion. |

| Aluminum (Al) | In aluminum-zinc steel, it accounts for about 55% | Forms a dense oxide film with zinc, which has excellent corrosion resistance. |

| Silicon (Si) | In aluminum-zinc steel, it accounts for about 1.6% | Improves the corrosion resistance and processing performance of the aluminum-zinc alloy coating. |

| Mechanical Property | Parameter |

|---|---|

| Yield Strength | Usually 220 – 550 MPa. For example, pre – painted galvanized color steel tiles have a yield strength of 220 – 350 MPa, and pre – painted galvalume color steel tiles have a yield strength of 350 – 550 MPa. |

| Tensile Strength | Generally ≥280 MPa for common – grade base metal (such as TDC51D+Z), and ≥350 MPa for high – strength grades. |

| Elongation | ≥20% for TDC51D+Z base metal. |

| Bending Resistance | Can be bent according to certain requirements without cracking. The specific bending radius and angle depend on the thickness and strength grade of the color steel tile. |

| Impact Resistance | Can withstand a certain degree of impact without obvious damage, and the impact resistance is related to the thickness and material properties of the color steel tile. |

| Single – square Load – bearing Capacity | For example, a 0.5mm – thick color steel tile (with a wave height of 30mm) has a static load – bearing capacity of about 80 – 120 kg/m². |

| Section Modulus | Different for various models. For example, for the YX25 – 183.3 – 916 model, when the thickness is 0.5mm, the section inertia is 12.59 cm⁴/m, and the section resistance is 10.45 cm³/m; when the thickness is 0.6mm, the section inertia is 15.71 cm⁴/m, and the section resistance is 13.33 cm³/m. |

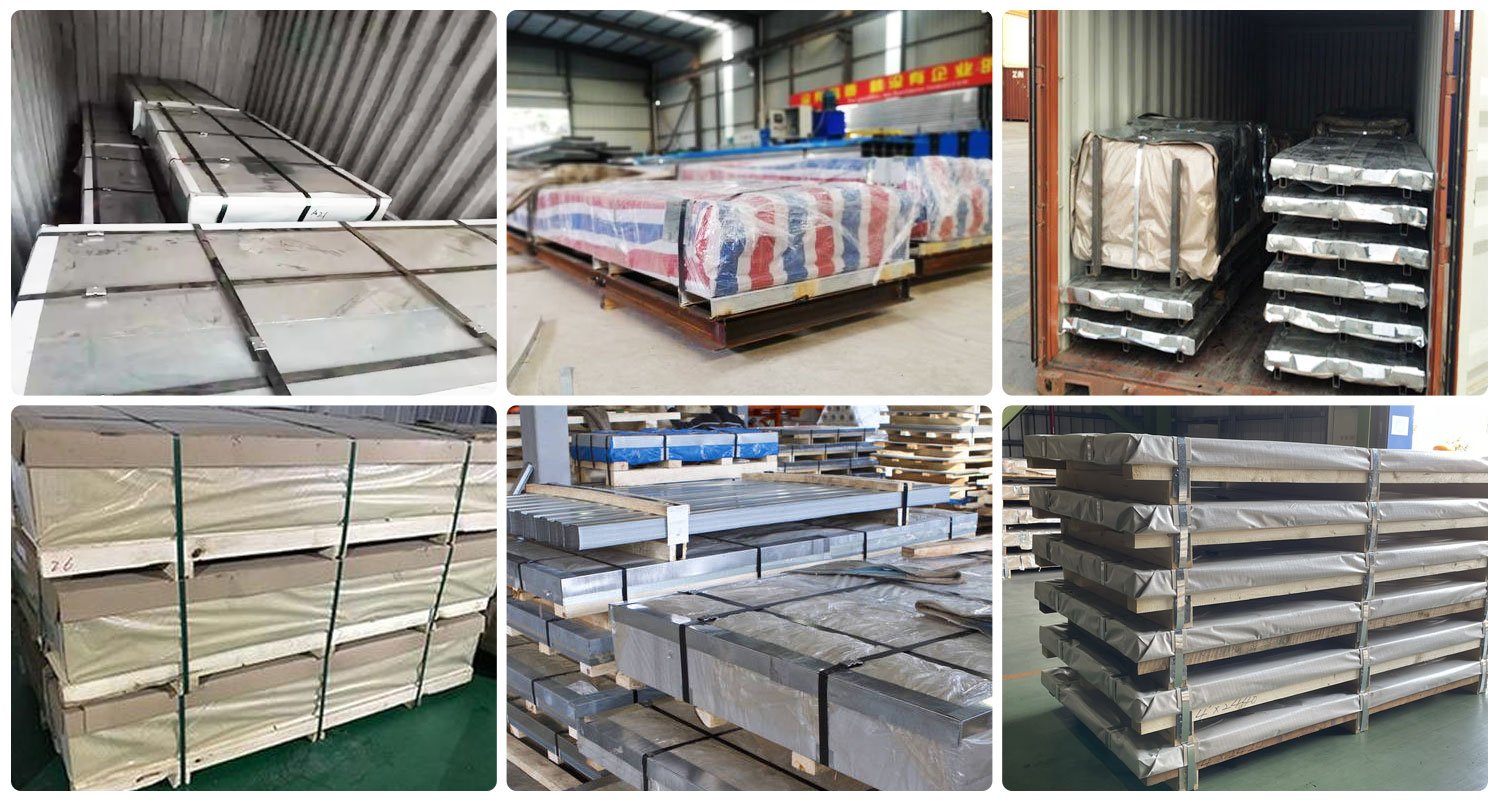

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.