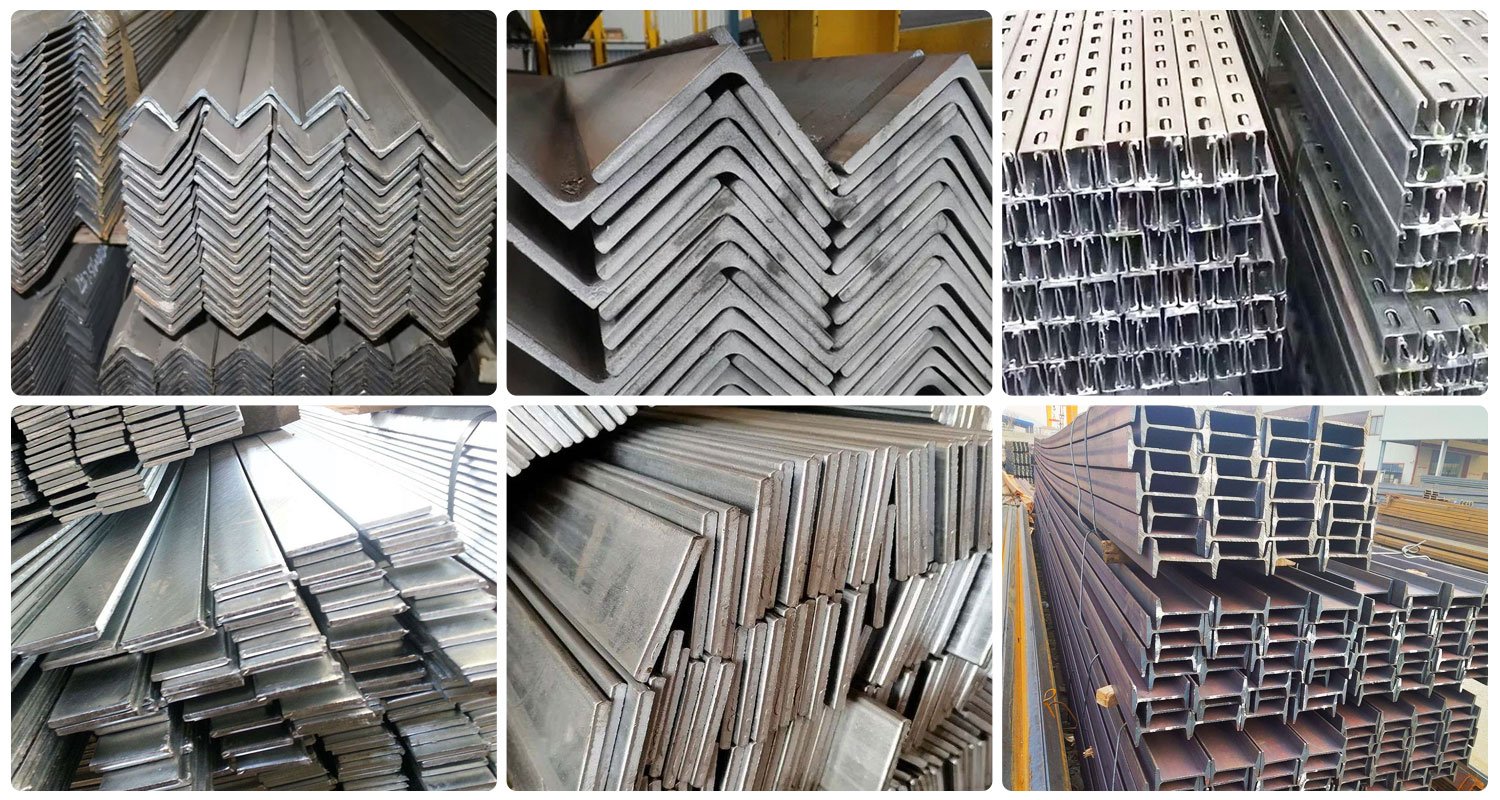

Carbon steel I-beams

Product Introduction

ASTM A36 Carbon Steel I – beams

| Property | Value |

|---|---|

| Chemical Composition (Maximum Content) | Carbon: 0.26% Manganese: Not specified Phosphorus: 0.040% Sulfur: 0.050% Silicon: 0.40% |

| Mechanical Properties | Yield Strength: 250MPa Tensile Strength: 400 – 550MPa Elongation: 23% |

EN S235JR Carbon Steel I – beams

| Property | Value (t≤16mm) |

|---|---|

| Chemical Composition (Maximum Content) | Carbon: 0.19% Silicon: Not specified Manganese: 1.5% Phosphorus: 0.045% Sulfur: 0.045% Copper: 0.60% Nitrogen: 0.014% |

| Mechanical Properties | Yield Strength: 235MPa Tensile Strength (3mm≤t≤40mm): 360 – 510MPa Elongation (3mm≤t≤16mm): 26% Charpy V – notch Test Temperature: 20℃ Charpy V – notch Impact Energy (Longitudinal): 27J |

ASTM A572 Grade 50 Carbon Steel I – beams

| Property | Value |

|---|---|

| Chemical Composition (Maximum Content) | Carbon: 0.23% Manganese: 0.50 – 1.60% Silicon: 0.40% Vanadium: 0.15% Columbium: 0.05% Phosphorus: 0.035% Sulfur: 0.045% |

| Mechanical Properties | Yield Strength: 345MPa Tensile Strength: 450 – 585MPa Elongation: 21% |

ASTM A36 Carbon Steel I – beams

| Element | Maximum Content(%) |

|---|---|

| Carbon | 0.26 |

| Phosphorus | 0.04 |

| Sulfur | 0.05 |

| Silicon | ≤0.40 |

| Manganese | Not specified |

| Note | Copper content can be specified as required. |

ASTM A572 Grade 50 Carbon Steel I – beams

| Element | Maximum Content(%) |

|---|---|

| Carbon | 0.23 |

| Manganese | 0.50 – 1.60 |

| Silicon | 0.40 |

| Vanadium | 0.15 |

| Columbium | 0.05 |

| Phosphorus | 0.035 |

| Sulfur | 0.045 |

EN S235JR Carbon Steel I – beams

| Element | Maximum Content(%) |

|---|---|

| Carbon | 0.17 |

| Manganese | 1.4 |

| Phosphorus | 0.035 |

| Sulfur | 0.035 |

| Silicon | Not specified |

Chinese Standard Q235B Carbon Steel I – beams

| Element | Maximum Content(%) |

|---|---|

| Carbon | 0.2 |

| Manganese | 1.4 |

| Phosphorus | 0.045 |

| Sulfur | 0.045 |

| Silicon | 0.35 |

Chinese Standard Q345B Carbon Steel I – beams

| Element | Maximum Content(%) |

|---|---|

| Carbon | 0.2 |

| Manganese | 1.7 |

| Phosphorus | 0.035 |

| Sulfur | 0.035 |

| Silicon | 0.5 |

| Niobium | 0.07 |

| Vanadium | 0.2 |

| Titanium | 0.2 |

ASTM A36 Carbon Steel I-Beams

(Compliant with ASTM A36/A36M – Standard Specification for Carbon Structural Steel)

| Mechanical Property | Value (Typical) | Notes |

|---|---|---|

| Yield Strength (Min) | 250 MPa (36 ksi) | For sections with thickness ≤ 203 mm |

| Tensile Strength | 400–550 MPa (58–80 ksi) | |

| Elongation (Min) | 23% | For specimens with gauge length = 50 mm |

| Charpy V-Notch Impact Energy | Not specified | Optional; typically ≥ 27 J at 20°C if required |

| Modulus of Elasticity (E) | 200 GPa (29,000 ksi) | Typical for carbon steels |

| Poisson’s Ratio | 0.3 | At room temperature |

ASTM A572 Grade 50 Carbon Steel I-Beams

(Compliant with ASTM A572/A572M – Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel)

| Mechanical Property | Value (Min/Range) | Notes |

|---|---|---|

| Yield Strength (Min) | 345 MPa (50 ksi) | For sections with thickness ≤ 12.7 mm |

| Tensile Strength | 450–585 MPa (65–85 ksi) | |

| Elongation (Min) | 21% | For specimens with gauge length = 50 mm |

| Charpy V-Notch Impact Energy (Min) | 27 J (20 ft-lb) | At -40°C (-40°F) for thickness ≤ 50 mm |

| Modulus of Elasticity (E) | 200 GPa (29,000 ksi) | Typical for high-strength low-alloy steel |

| Poisson’s Ratio | 0.3 | At room temperature |

EN S235JR Carbon Steel I-Beams

(Compliant with EN 10025-2:2019 – Hot-Rolled Products of Non-Alloy Structural Steels)

| Mechanical Property | Value (Min/Range) | Notes |

|---|---|---|

| Yield Strength (Min) | 235 MPa | For thickness ≤ 16 mm; decreases slightly for thicker sections (e.g., 225 MPa for 16–40 mm) |

| Tensile Strength | 360–510 MPa | For thickness 3–40 mm |

| Elongation (Min) | 26% | For thickness 3–16 mm (gauge length = 5.65×√S₀, where S₀ = original cross-sectional area) |

| Charpy V-Notch Impact Energy (Min) | 27 J | Longitudinal specimens at 20°C |

| Modulus of Elasticity (E) | 210 GPa | Typical for European structural steels |

| Poisson’s Ratio | 0.3 | At room temperature |

GB/T Q235B Carbon Steel I-Beams

(Compliant with GB/T 700-2006 – Carbon Structural Steels; GB/T 11263-2017 – Hot-Rolled H, I, and Channel Sections)

| Mechanical Property | Value (Min/Range) | Notes |

|---|---|---|

| Yield Strength (Min) | 235 MPa | For thickness ≤ 16 mm |

| Tensile Strength | 375–500 MPa | For thickness 3–40 mm |

| Elongation (Min) | 26% | For specimens with gauge length = 50 mm |

| Charpy V-Notch Impact Energy (Min) | 27 J | At 20°C (transverse specimens) |

| Modulus of Elasticity (E) | 206 GPa | Typical for Chinese carbon structural steels |

| Poisson’s Ratio | 0.3 | At room temperature |

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.