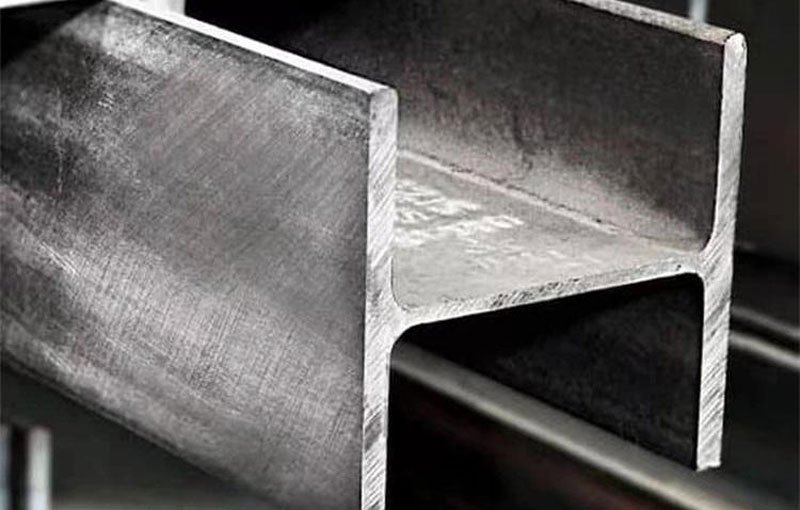

Galvanized I-beam

Product Introduction

Galvanized Channel Steel Parameter Table

| Model | Dimensions (mm) (Height×Leg Width×Web Thickness) | Weight (kg/m) | Cross – sectional Area (cm²) |

|---|---|---|---|

| 5# | 50×37×4.5 | 5.438 | 6.03 |

| 6.3# | 63×40×4.8 | 6.634 | 7.37 |

| 8# | 80×43×5.0 | 8.045 | 8.94 |

| 10# | 100×48×5.3 | 10.007 | 11.1 |

| 12# | 120×53×5.5 | 12.059 | 13.4 |

| 14# | 140×58×6.0 | 14.535 | 16.1 |

| 16# | 160×63.5×6.5 | 17.24 | 19.1 |

| 20# | 200×73×7.0 | 20.51 | 22.8 |

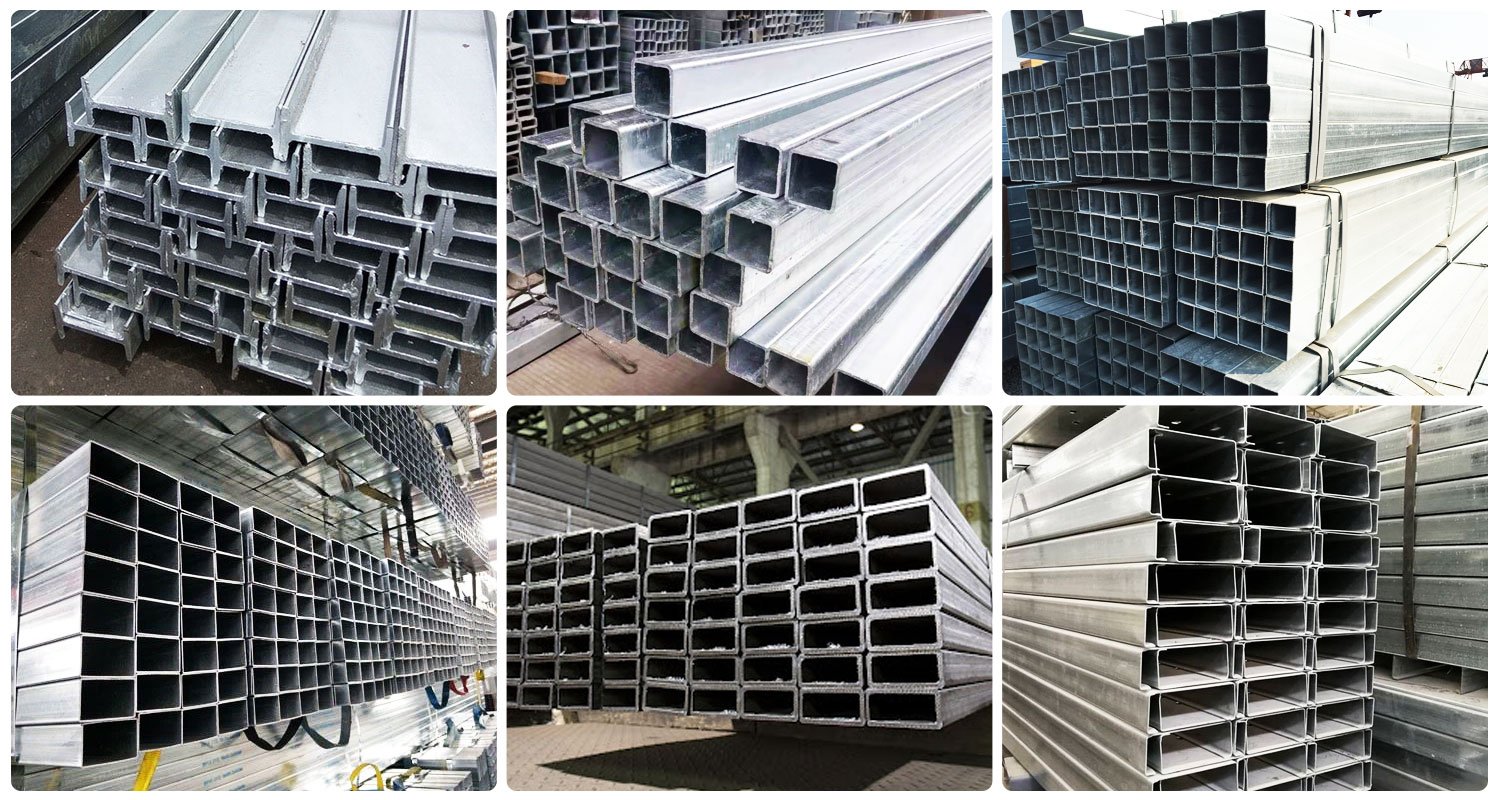

Galvanized C – shaped Steel Parameter Table

| Model | Dimensions (mm) (Height×Flange×Lip×Thickness) |

|---|---|

| C1806020*1.8 | 180×60×20×1.8 |

| C2006020*2.0 | 200×60×20×2.0 |

Galvanized Z – shaped Steel Parameter Table

| Model | Dimensions (mm) (Height×Flange×Lip×Thickness) |

|---|---|

| Z2007020*2.0 | 200×70×20×2.0 |

| Z250202.5 | 250×20×20×2.5 |

Parameter Table of Galvanized Steel Studs and Tracks

| Product | Specification (mm) | Thickness (mm) | Zinc Coating (g/m²) |

|---|---|---|---|

| Main Channel | 38×12 | 0.8, 1.0 | 40 – 275 |

| 50×15 | 0.8, 1.0, 1.2 | ||

| Furring Channel | 50×19 | 0.4, 0.45, 0.5 | |

| 60×27 | 0.4, 0.5, 0.6 | ||

| C – stud | 50×40 | 0.4, 0.45, 0.5, 0.6 | |

| 50×35 | 0.4, 0.5, 0.6 | ||

| 70×40 | 0.4, 0.5, 0.6 | ||

| 75×45 | 0.45, 0.5, 0.6 | ||

| U – track | 50×40 | 0.4, 0.45, 0.5, 0.6 | |

| 50×30 | 0.4, 0.5, 0.6 | ||

| 70×30 | 0.4, 0.5, 0.6 | ||

| 70×35 | 0.4, 0.5, 0.6 | ||

| 75×35 | 0.4, 0.45, 0.5, 0.6 | ||

| 75×25 | 0.4, 0.45, 0.5 |

| Element | Function | Content Range (wt%) | Notes |

|---|---|---|---|

| Iron (Fe) | Primary component of the substrate; determines basic strength | ≥98.5 | Balance (main component after other elements are accounted for) |

| Carbon (C) | Improves strength but reduces ductility | ≤0.22 (Q235/S235JR); ≤0.20 (Q355/S355JR) | Excess C increases brittleness and impairs zinc coating adhesion |

| Manganese (Mn) | Refines grain structure; enhances strength and toughness | 0.30–1.40 (Q235/S235JR); 0.50–1.60 (Q355/S355JR) | Partially replaces C to reduce brittleness risk |

| Silicon (Si) | Deoxidizer in steelmaking; slightly improves strength | ≤0.35 (Q235/S235JR); ≤0.55 (Q355/S355JR) | Excess Si reduces weldability and degrades coating quality |

| Sulfur (S) | Harmful element; causes “hot brittleness” (cracking during heating/processing) | ≤0.045 (Q235/S235JR); ≤0.040 (Q355/S355JR) | Strictly limited to prevent cracking during forming or loading |

| Phosphorus (P) | Harmful element; causes “cold brittleness” (cracking at low temperatures) | ≤0.045 (Q235/S235JR); ≤0.040 (Q355/S355JR) | Controlled to avoid brittle fracture in low-temperature environments |

| Copper (Cu) | (Optional) Enhances atmospheric corrosion resistance | ≤0.30 (for weather-resistant substrates only) | Non-essential; added only for specific outdoor corrosion requirements |

| Property Category | Key Parameter | Definition | Significance for Galvanized Profiles |

|---|---|---|---|

| Tensile Properties | Yield Strength (Rₑₕ) | The stress at which the material begins to deform permanently (plastic deformation) | Ensures the profile does not deform under design loads (e.g., structural supports, framing). |

| Tensile Strength (Rₘ) | The maximum stress the material can withstand before breaking | Determines the profile’s load-bearing limit to prevent structural failure. | |

| Elongation After Fracture (A) | The percentage of length increase before the material breaks | Indicates ductility—critical for forming (e.g., bending, rolling) and absorbing impact energy. | |

| Bending Properties | Bending Strength/Formability | Ability to withstand bending without cracking or permanent damage | Essential for profiles used in construction (e.g., C-channels, U-sections) that require on-site bending. |

| Impact Properties | Charpy Impact Energy (Kv) | Energy absorbed by the material during sudden impact (at specific temperatures) | Ensures performance in low-temperature environments (e.g., cold regions) to avoid brittle fracture. |

| Hardness | Brinell Hardness (HB) / Vickers Hardness (HV) | Resistance to surface indentation | Relevant for profiles exposed to wear (e.g., industrial rails) but less critical for general construction. |

Packaging and transportation

8unit in 1*20GP container , 12units in 1*40HQ container, Fumigated wood tray and 10mm wire fixed.